kobelco bucket

-

Hot

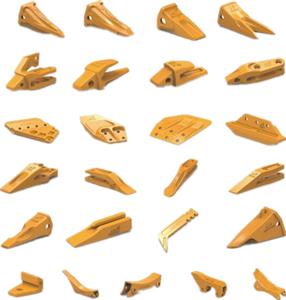

Kobelco Excavator Bucket Teeth

Selection of kobelco bucket teeth: When purchasing bucket teeth for excavators, the first thing to look at is the working environment in which the bucket teeth are used to determine what type of kobelco bucket teeth. First, generally dig soil, loose sand, etc. with flat kobelco bucket teeth. Secondly, RC-type bucket teeth are used for digging massive hard rock, and TL-type kobelco bucket teeth are generally used for digging massive coal seams. In addition, in the actual operation process, most people like general-purpose RC bucket teeth. Kyushan recommends that you do not use RC type bucket teeth, it is best to use flat kobelco bucket teeth, because RC bucket teeth wear out after a period of time, increase the digging resistance and waste power, while the flat bucket teeth always maintain a sharp surface during the wear process, reducing the digging resistance, Save fuel.

Email Details -

Hot

All Kinds Of Kobleco Bucket Excavator

Supiror Performance of Kobelco Bucket 1. Quenched&Tempered Alloy Steel 140,000-150,000 psi MIN. Yield, 320-400 BHN is used in cutting edge, lower sidecutter sections, wear strips & side wear plates. 2. Optimized profile for better filling & dumping Enhanced Durability of Kobelco buckets 1. Strategic placement of HARDOX500 wear material in the cutting edge, side cutter and bottom corner to reduce wear. 2. High strenght wear strip configuration, affords the best possible protection to the bottom of the kobelco bucket. 3. All welding is done by skilled worker with, at least, 4 years of excavator attachments' welding experience. Superior Lead Time 1. Most sizes available in 5-7 working days(excluded shipping) Reasonable Price of kobelco bucket 1. Manufactured in China with lower labor cost and guaranteed quality.

Email Details