Excavator Bucket Tooth

-

Hot

Professional Excavator Bucket Teeth Supplier

We are professional excavator bucket teeth suppliers

Send Email Details

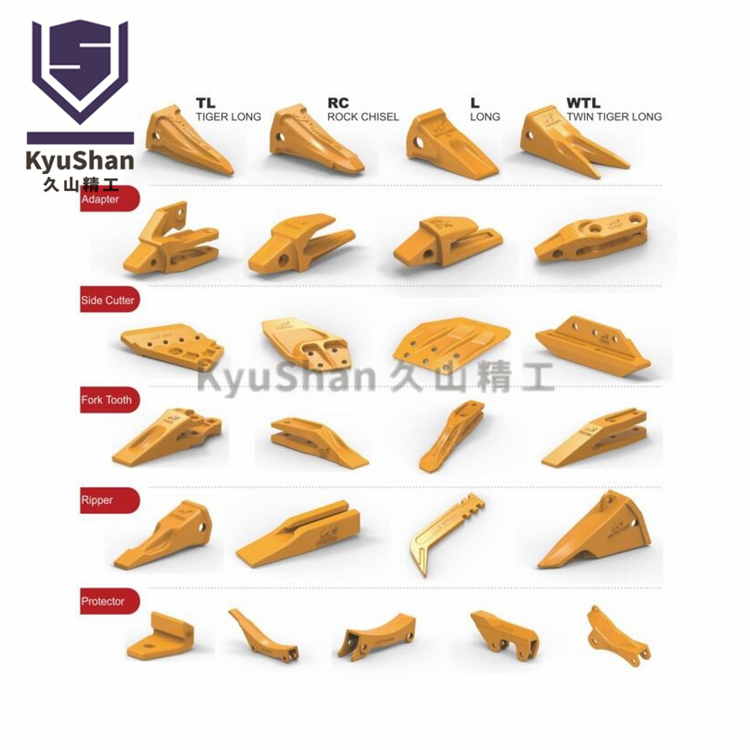

Excavator bucket teeth are important consumable parts on excavators, similar to human teeth. They are combined bucket teeth composed of tooth bases and tooth tips, which are connected by pins. Since the worn out part of the bucket teeth is the tip of the tooth, just replace the tip.

Classification according to the environment in which the bucket teeth of the excavator are used. Excavator bucket teeth can be divided into rock teeth (for iron ore, quarry, etc.), earthwork teeth (for excavating soil, sand, etc.), conical teeth (for coal mines). According to the bucket tooth seat: the excavator bucket tooth can be divided into vertical pin bucket tooth (mainly Hitachi excavator), horizontal pin bucket tooth (Komatsu excavator, Carter excavator, Daewoo excavator, Kobelco excavator, etc.) , Rotary bucket teeth (V series bucket teeth). -

Hot

All Part Numbers Excavator Tooth Pin For All Brands Excavator

Material:high quality 40cr steel round bar is the raw material of our excavator tooth pin.

Send Email Details

Surface: Various surface treatment for our excavator tooth pin like blackening,galvanied...

Products: Complete product system of all kinds of excavator tooth pins. We can manufact all the tooth pins you need. -

Hot

All Kinds Of Bucket Tooth Adapter For All Brands Excavators

The bucket tooth adapter structure is mainly composed of three parts, the head, the upper leg and the lower leg. The head cooperates with the inner cavity of the bucket tooth sleeve to become the mounting seat of the bucket tooth sleeve. The front ends of the upper and lower legs are both connected with the rear end of the head.

Send Email Details -

Hot

All Sizes Cat Bucket Teeth Adapter

Our Cat bucket teeth adapters were made by advanced forging technology, independently develop custom forged special steel, improve its internal structure and mechanical properties through precision forging, and unique heat treatment process, the product has high strength, high wear resistance, fatigue resistance, and product life. Extends several times, thereby reducing maintenance time and construction costs.

Send Email Details

The wear-resistant cat bucket teeth adapters and the preparation method thereof solve the problems of general mechanical properties, short service life and high production cost of the existing tooth seat. The composition and mass percentage of the wear-resistant tooth seat of the present invention are: C: 0.22-0.25%, Mn: 0.90-1.30%, Si: 1.30-1.70%, Cr: 1.20-1.50%, Al: 0.02-0.06%, Ni: 0.15 to 0.20%, Mo: 0.10 to 0.15%, and the balance is Fe and inevitable impurities. -

Hot

Excavator Spare Parts Komatsu Bucket Teeth And Adapters

The role of komatsu bucket teeth and adapters

Send Email Details

1. Protect the bucket as a whole

komatsu bucket teeth and adapters are wear parts. Since the bucket is worn out when shoveling soil or stones, the addition of the bucket teeth protects the bucket.

2. Make the operation more delicate

We drove the excavator to draw dragons and phoenixes on the ground, and imagine that the fine operation is impossible without the reference of komatsu bucket teeth and adapters.

3. Easy to dig and shovel

The bucket teeth are conical with a gap in the middle. The force of the entire bucket is smaller and the pressure becomes larger, making it easier to shovel and dig things up.

4. After digging hard things, the bucket teeth of the bucket have a buffering effect on the whole machine.

Advantage of komatsu bucket teeth and adapters:

1. high wear resistance,

2. The bucket teeth and the tooth seat fit precisely, and they are tightly locked with the bucket tooth pins.

3. High reliability, hard and tough, with high fatigue resistance. -

Hot

Kubota Excavator Bucket Teeth

Our company has been selling Kubota excavator bucket teeth for many years and has accumulated rich experience in the long-term market. Our Kubota bucket teeth are available in a variety of quality levels. And our sales will recommend to you the most economical choice according to your application scenario. Make your excavator more efficient.

Send Email Details -

Hot

Caterpillar Cat Excavator Bucket Teeth Replacement

Cat excavator teeth replacement cycle:

Send Email Details

The replacement cycle of the cat excavator teeth should be determined according to the construction environment and the degree of wear of the bucket teeth. For example, the excavator has been doing earthwork work, so the wear degree of the cat excavator teeth is relatively small, and it is generally replaced every 4-5 months. .

If it is a rock-type cat excavator teeth, the frequency of replacing the bucket teeth is faster. Like granite, it takes about a week to replace the bucket teeth. Of course, this cycle is not fixed, and it depends on the quality of the bucket teeth and the meticulousness of the actual operation. and so on to determine the replacement frequency of bucket teeth. -

Hot

Cheaper Best Quality Komatsu pc200 Bucket Teeth

Buying Guide of komatsu pc200 bucket teeth:

Send Email Details

If your excavator is doing earthwork, the frequency and demand for replacing komatsu pc200 bucket teeth every year is relatively small, then it is recommended that you choose forging and casting komatsu pc200 bucket teeth, although the price is much higher, but the service life, production process and quality are all is optimal.

If the requirement for the number of bucket teeth is relatively large, then the cost performance of the komatsu pc200 bucket teeth is required to be relatively high, then the precision cast bucket teeth perform well in terms of price, quality, cost performance and wear resistance. -

Hot

Komatsu Excavator Bucket Teeth

1. During the use of the komatsu bucket teeth of the excavator, the outermost teeth of the bucket wear 30% faster than the innermost teeth. After a period of use, the inner and outer komatsu bucket teeth of the bucket should be replaced.

Send Email Details

2. The excavator driver should pay attention to the angle of digging during the operation, try to master it when digging, and the komatsu bucket teeth are perpendicular to the working face when digging down, so as to avoid breaking the bucket teeth due to excessive inclination.

3. Be careful not to swing the digging arm left and right under the condition of large resistance, so that the komatsu bucket teeth and tooth adapter are easily broken due to excessive force on the left and right sides, and the design of the force on the left and right is not considered.