How To Extend The Service Life Of Bucket Teeth

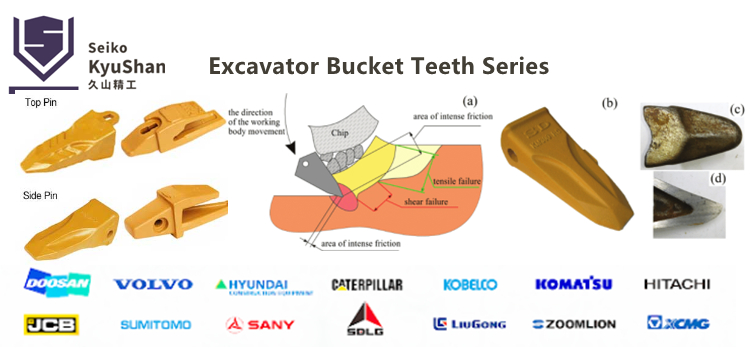

Bucket teeth are an important part of the excavator and the most easily damaged part. They are combined bucket teeth composed of a tooth base and a tooth tip, and the two are connected by a pin shaft.

Since the worn out part of the bucket teeth is the tip of the tooth, it is only necessary to replace the tip. Therefore, a good bucket tooth is related to the issue of cost performance. The brand bucket tooth produced by Jinan Songteli Construction Machinery Co., Ltd. is the guarantee of quality.

The manufacturing process of bucket teeth is mainly casting, sand casting and precision casting. The cost of forging bucket teeth is high, and the sales volume is very small.

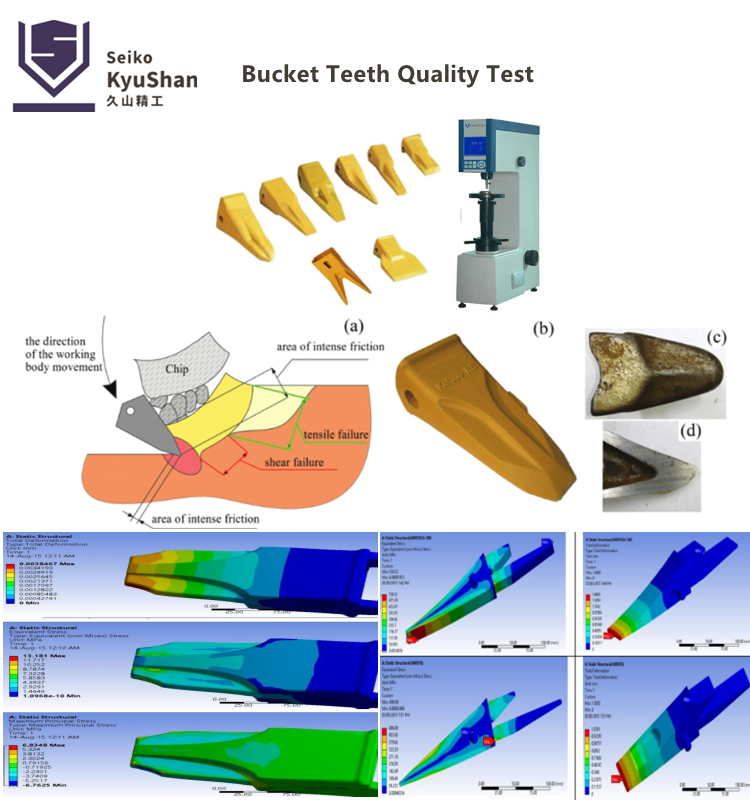

Failure analysis of bucket teeth:

1. Failure form Bucket teeth are subjected to different degrees of wear and impact under different working conditions, resulting in different degrees and different forms of failure.

2. Analysis and discussion (1) Force analysis The working face of bucket teeth is in contact with the object to be excavated, and the force is different in different working stages during a complete excavation process. (2) Process analysis Take two samples from the front and rear working surfaces respectively, and grind them flat for hardness test. (3) Microstructure analysis Metallographic observation shows that the matrix is mainly black flaky structure, and the insert structure is composed of two parts: white block and black thin piece, and there are more white block structures far away from the cross-section area, and further microhardness Tests have shown that the white bulk structure is ferrite, and the black flaky structure is troostite or a mixed structure of troostite and pearlite. (4) Performance analysis According to the wear test on the MLD-10 wear tester, the wear resistance of the matrix and the insert under the small impact abrasive wear test condition is better than that of the quenched 45 steel.