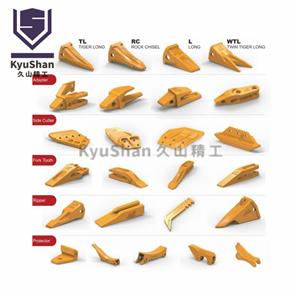

excavator bucket teeth suppliers

-

Hot

Professional Excavator Bucket Teeth Supplier

We are professional excavator bucket teeth suppliers Excavator bucket teeth are important consumable parts on excavators, similar to human teeth. They are combined bucket teeth composed of tooth bases and tooth tips, which are connected by pins. Since the worn out part of the bucket teeth is the tip of the tooth, just replace the tip. Classification according to the environment in which the bucket teeth of the excavator are used. Excavator bucket teeth can be divided into rock teeth (for iron ore, quarry, etc.), earthwork teeth (for excavating soil, sand, etc.), conical teeth (for coal mines). According to the bucket tooth seat: the excavator bucket tooth can be divided into vertical pin bucket tooth (mainly Hitachi excavator), horizontal pin bucket tooth (Komatsu excavator, Carter excavator, Daewoo excavator, Kobelco excavator, etc.) , Rotary bucket teeth (V series bucket teeth).

bucket teeth suppliers case backhoe bucket teeth excavator bucket teeth for sale tooth bar for loader bucketEmail Details -

Hot

All Kinds Of Fuel Oil Caterpillar Filters For Excavator

The function of the oil filter is to caterpillar filters out the sundries, gums and moisture in the oil, and deliver clean oil to each lubricating part. In order to reduce the frictional resistance between the relatively moving parts in the engine and reduce the wear of the parts, the oil is continuously transported to the friction surface of each moving part to form a lubricating oil film for lubrication. The engine oil itself contains a certain amount of gum, impurities, moisture and additives. At the same time, during the working process of the engine, the introduction of metal wear debris, the entry of debris in the air, and the generation of oil oxides make the debris in the oil gradually increase. If the oil directly enters the lubricating oil circuit without being filtered, the sundries contained in the oil will be brought into the friction surface of the moving pair, which will accelerate the wear of parts and reduce the service life of the engine.

Email Details -

Hot

Hyundai Excavator Bucket Teeth

Speciality of hyundai bucket teeth: 1. Adjustable cutting angle by rotating up to 1800 in its holder; 2. Easy hyundai bucket teeth replacement with purpose- built extraction tool; 3. Compact construction facilitating complicated cutting geometry; 4. High durability due to wear-resistant manganese steel; 5. Tungsten carbide inserts on cutting edge and on both flanks; 6. Optimum transition from teeth to teeth holder to cutting blade; 7. Each hyundai bucket teeth is positioned in optimum cutting geometry; 8. High strength resulting from forging; 9. Optimal protection of teeth holder.

Email Details