- Kyushan

- China

- 3-5 working days

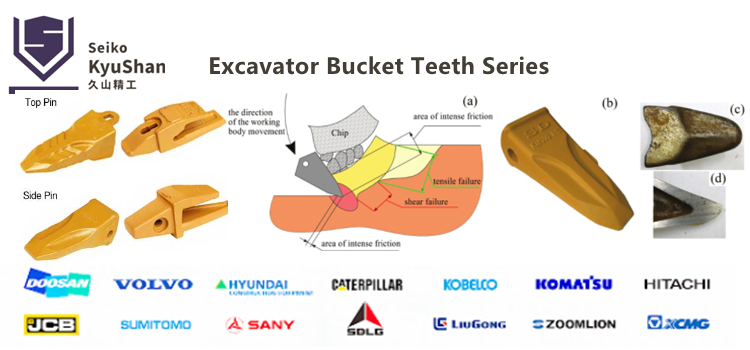

We are professional excavator bucket teeth suppliers

Excavator bucket teeth are important consumable parts on excavators, similar to human teeth. They are combined bucket teeth composed of tooth bases and tooth tips, which are connected by pins. Since the worn out part of the bucket teeth is the tip of the tooth, just replace the tip.

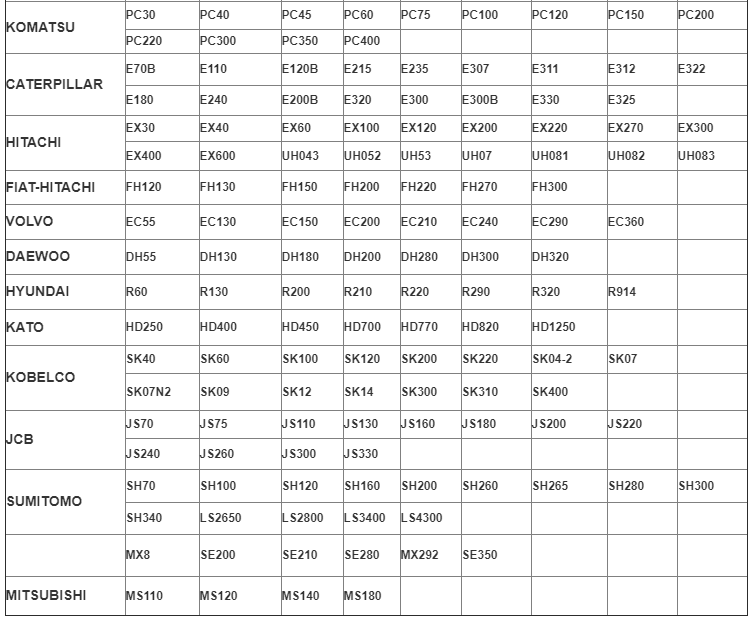

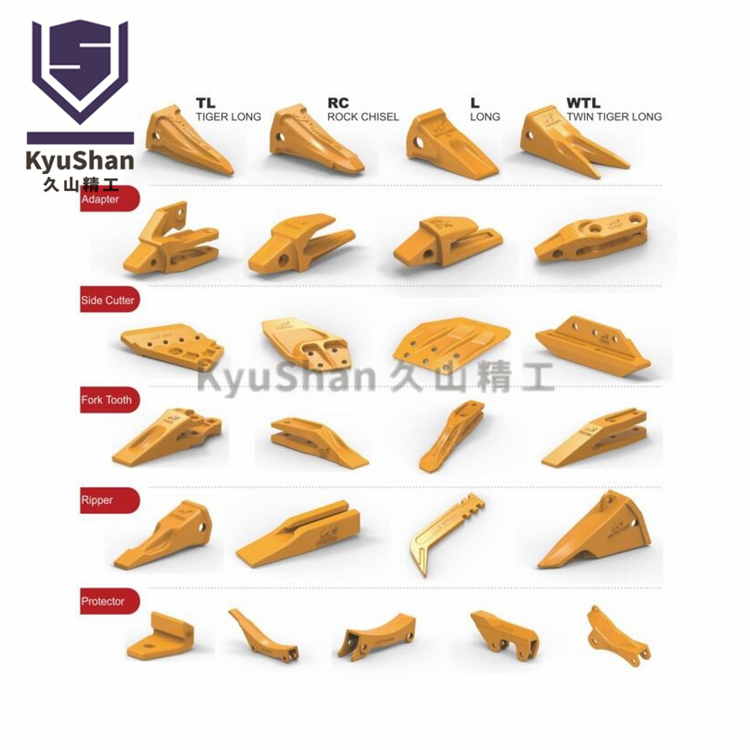

Classification according to the environment in which the bucket teeth of the excavator are used. Excavator bucket teeth can be divided into rock teeth (for iron ore, quarry, etc.), earthwork teeth (for excavating soil, sand, etc.), conical teeth (for coal mines). According to the bucket tooth seat: the excavator bucket tooth can be divided into vertical pin bucket tooth (mainly Hitachi excavator), horizontal pin bucket tooth (Komatsu excavator, Carter excavator, Daewoo excavator, Kobelco excavator, etc.) , Rotary bucket teeth (V series bucket teeth).

Manufacturers Professional Excavator Bucket Teeth Supplier

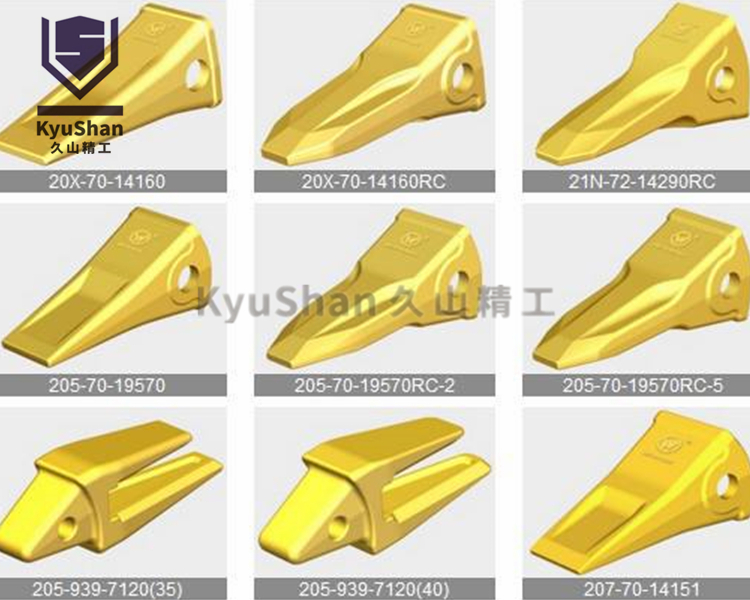

| Name | Manufacturers Professional Excavator Bucket Teeth Supplier |

| Product Number | All Part Numbers You Need |

| Condition | Original Brand New |

| MOQ | 1 Piece |

| Payment | T/T, Western Union, Paypal, etc |

| Standard or Nonstandard | Standard |

| Delivery Time | In 3 Days |

| Packing | Wooden Box |

| Warranty | 6 Months |

| Transport | By sea/air/express (DHL/FEDEX/TNT/UPS/EMS/City-line) |

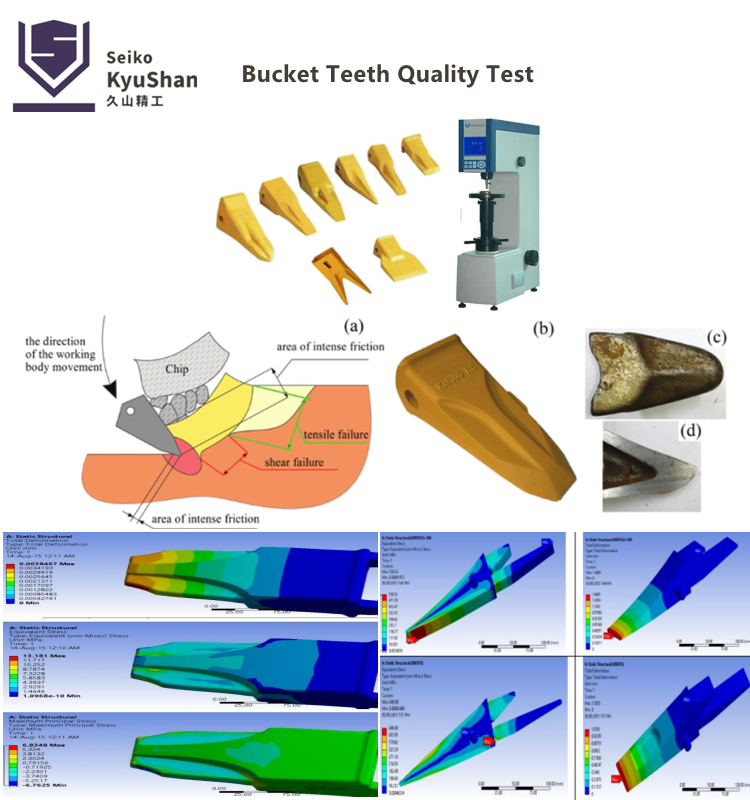

Professional excavator bucket teeth suppliers:The difference between forged bucket teeth and cast bucket teeth

Compared with castings, the metal structure and mechanical properties can be improved after forging. After the casting structure is deformed by the forging method, due to the deformation and recrystallization of the metal, the original coarse dendrites and columnar grains become an equiaxed recrystallized structure with finer grains and uniform size, which makes the original segregation and recrystallization in the ingot. Porosity, pores, slag inclusions, etc. are compacted and welded, and the organization becomes more compact, which improves the plasticity and mechanical properties of the metal.

The mechanical properties of castings are lower than those of forgings of the same material. In addition, the forging process can ensure the continuity of the metal fiber structure, so that the fiber structure of the forging is consistent with the shape of the forging, and the metal streamline is complete, which can ensure the parts have good mechanical properties and long service life. Precision die forging and cold extrusion are used. Forgings produced by processes such as warm extrusion and warm extrusion are incomparable to castings.

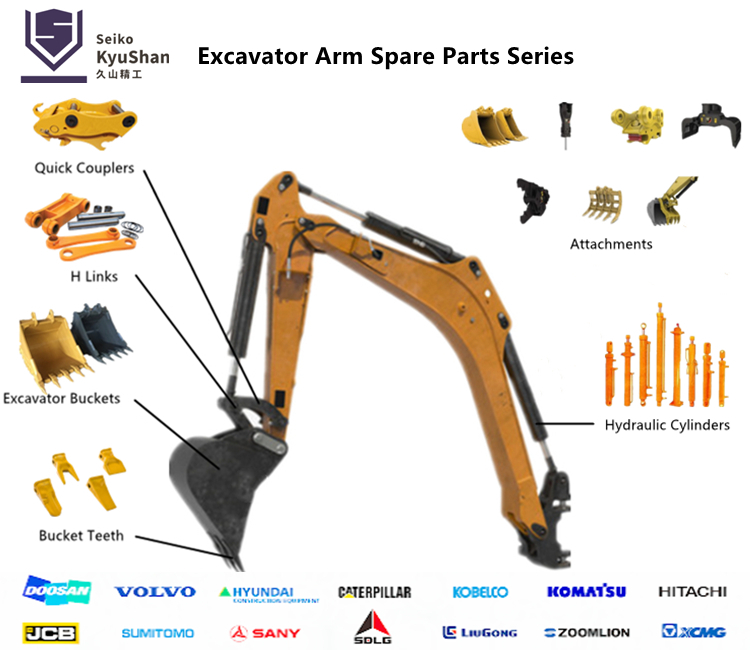

We are a comprehensive supplier of excavator accessories, if you have excavator accessories needs, please contact us, we will be glad to receive your inquiry!

Sales Manager:Liam Cheng Wechat/Whatsapp:+8616653175111