- Kyushan

- China

- 3-5 working days

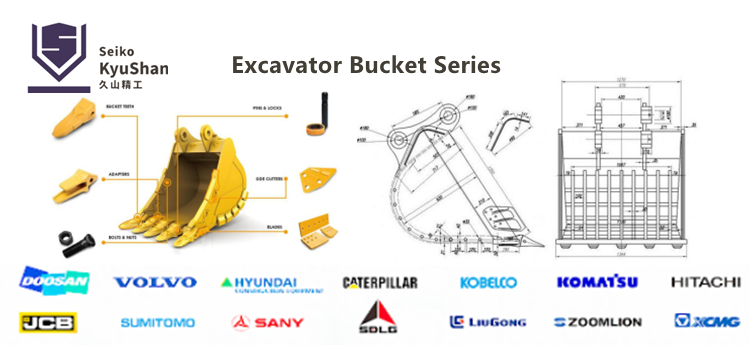

30 ton excavator buckets for salereinforcement and maintenance work instructions

Apply the car spring plate on the back and both sides of 30 ton excavator buckets for sale with a gap between the spring plates, and weld the edges on both sides of the bucket with relatively thick threaded steel bars. Or from both sides of the bucket, from the bucket back to the edge of the bucket teeth, reinforced with a double-axle truck half-shaft, then the bucket back is reinforced with a double-axle truck steel plate or track steel, and the two bucket roots are reinforced with a half-axle.

Factory Sales Cheaper 30 ton Excavator bucket For Sale

| Name | Factory Sales Cheaper 30 ton Excavator bucket For Sale |

| Product Number | All Part Numbers You Need |

| Condition | Original Brand New |

| MOQ | 1 Piece |

| Payment | T/T, Western Union, Paypal, etc |

| Standard or Nonstandard | Standard |

| Delivery Time | In 3 Days |

| Packing | Wooden Box |

| Warranty | 6 Months |

| Transport | By sea/air/express (DHL/FEDEX/TNT/UPS/EMS/City-line) |

Next, let's talk about the maintenance work of 30 ton excavator buckets for sale.

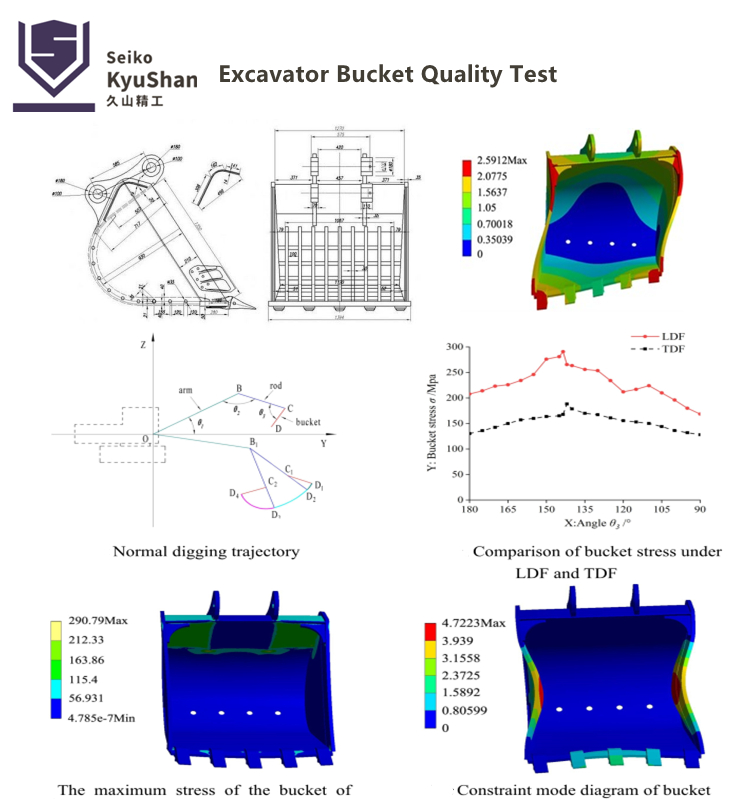

The 30 ton excavator buckets is the working device of the excavator. Because it is in direct contact with the work site such as soil and sand, it is required to be wear-resistant and impact-resistant. At the same time, because the bucket is the wearing part of the excavator, the general engineering excavator consumes 3 to 6 buckets in the average service period of 8 years, so there is a wide range of accessories market.

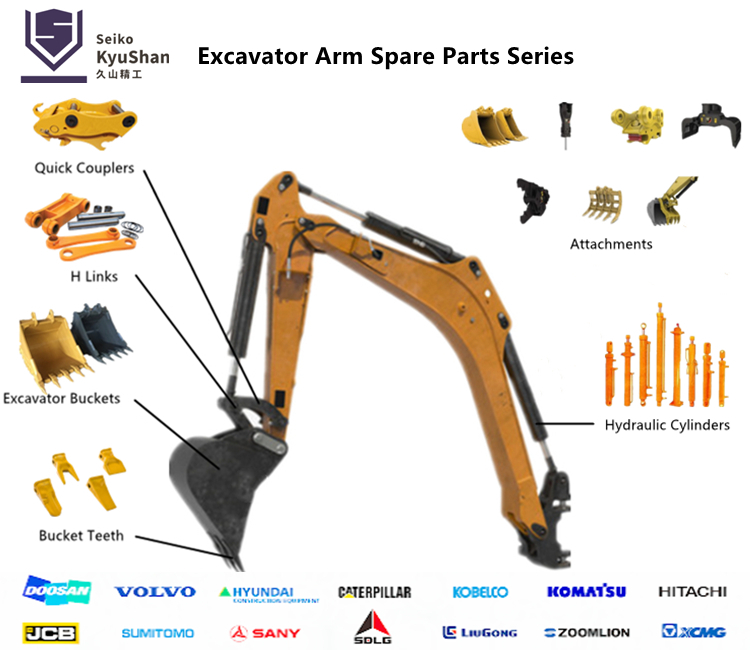

Due to the different work sites and construction objects, the same excavator can be equipped with a variety of buckets, but attention should be paid to the matching of the performance of the whole machine. However, in order to adapt to the rock operation, it is necessary to be careful to replace the ordinary bucket with a rock bucket of equal volume on the ordinary model, so as not to damage the performance of the whole machine and cause quality problems of the stick and boom due to improper use.

In order to prolong the service life of the bucket, in addition to ensuring sufficient strength and rigidity, it also puts forward higher requirements on fatigue strength and wear resistance. Usually, the bucket teeth are designed into two parts that can be replaced and welded together with the body, which is called a bucket. The tooth seat, the part that can be replaced is called bucket teeth. Bucket tooth seat, side edge plate and curved reinforcement plate of rock bucket should be made of materials with high strength, wear resistance and good welding performance.

We are a comprehensive supplier of excavator accessories, if you have excavator accessories needs, please contact us, we will be glad to receive your inquiry!

Sales Manager:Liam Cheng Wechat/Whatsapp:+8616653175111