- Kyushan

- China

- 3-5 working days

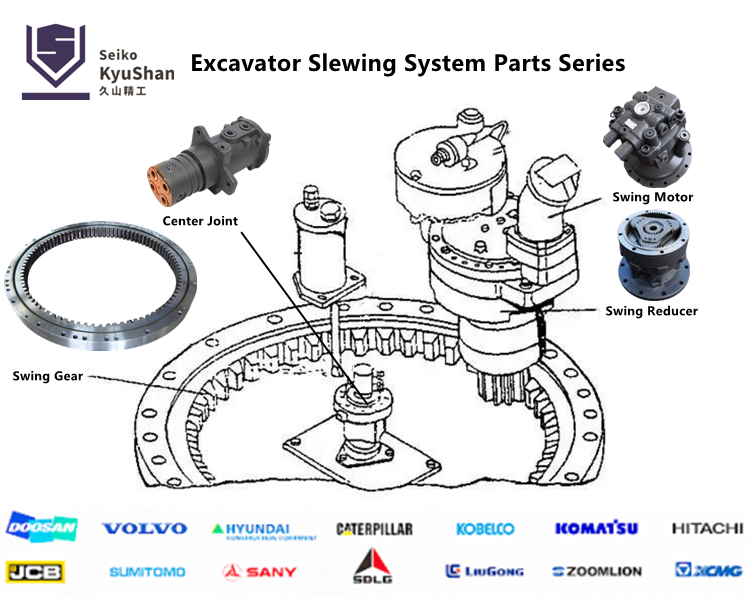

The working principle of the excavator hydraulic swivel joint:

When the excavator is working, its chassis and the upper operating body need to perform relative slewing motion. How to realize this movement that requires 360° rotation requires the core component of the excavator hydraulic swivel joint. When the excavator rotates, the hydraulic oil is delivered to the travel motor through the excavator hydraulic swivel joint, the hydraulic oil is connected from the main control valve to the internal cylinder, and the travel motor oil circuit is connected to the casing structure.

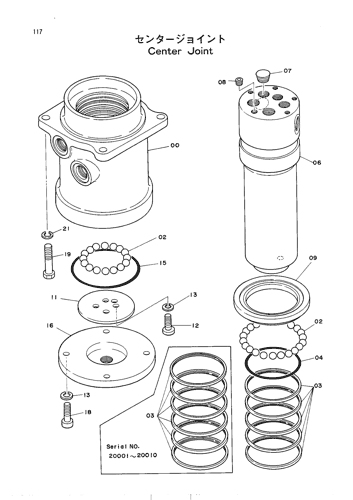

The inner cylinder is cast with annular grooves (ie oil passages) from top to bottom, and the outer casing is also cast with small grooves corresponding to the grooves (used to install the rotary joint sealing ring). When the machine rotates, the casing is fixed, and there is relative movement between the inner cylinder and the casing (the cylinder rotates in the casing). Because the oil passage is circular, the machine can be turned arbitrarily within the circumference range, and the casing oil passage can be kept connected with the corresponding mandrel oil passage to realize continuous rotation.

The central slewing joint for excavators consists of two parts: the inner cylinder and the outer shell, the shell is provided with a flange, which is fixed to the center of the slewing bearing, the shell is connected to the upper pipe, and the mandrel is connected to the lower pipe road.

Best Price High Quality Boom Cylinder Excavator For Sale

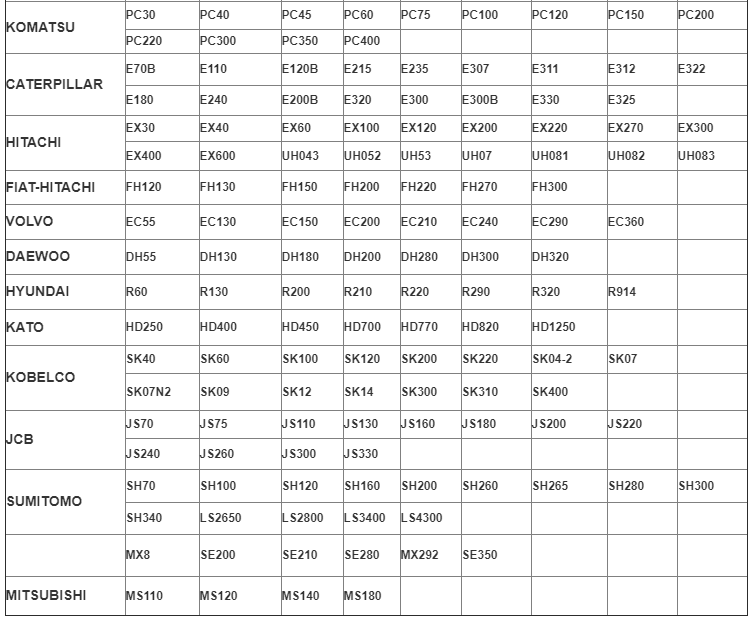

| Name | All Part Numbers Excavator Hydraulic Swivel Joint For Sale |

| Product Number | All Part Numbers You Need |

| Condition | Original Brand New |

| MOQ | 1 Piece |

| Payment | T/T, Western Union, Paypal, etc |

| Standard or Nonstandard | Standard |

| Delivery Time | In 3 Days |

| Packing | Wooden Box |

| Warranty | 6 Months |

| Transport | By sea/air/express (DHL/FEDEX/TNT/UPS/EMS/City-line) |

Analysis and solution of oil leakage failure in excavator hydraulic swivel joint:

In the process of using the excavator, the most common fault of the excavator hydraulic swivel joint is oil leakage. So why does the abnormal situation of oil leakage occur? It is mainly because the sealing ring of the central rotary joint is aged or severely worn and needs to be replaced.

For details, The specific operation steps for repairing the oil leakage of the excavator: first, remove the driver's cab, and then remove the boarding pipeline of the central rotary joint; Lower the entire platform; then disassemble the other pipelines of the excavator hydraulic swivel joint and remove it from the chassis; finally, there is a snap ring or a fixed thing under the excavator hydraulic swivel joint, remove it, repair and install and replace the sealing ring.

With the rapid growth of my country's economy, the country's infrastructure construction is also in full swing. Customers can choose the appropriate type of central rotary joint of the excavator according to the actual speed, pressure, interface diameter, flow rate, etc.

We are a comprehensive supplier of excavator accessories, if you have excavator accessories needs, please contact us, we will be glad to receive your inquiry!

Sales Manager:Liam Cheng Wechat/Whatsapp:+8616653175111