- Kyushan

- China

- 3-5 working days

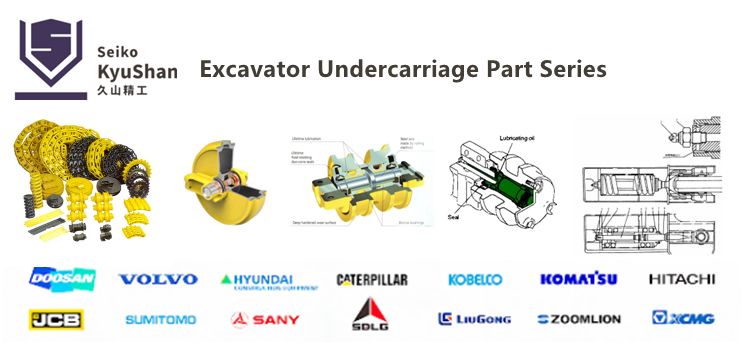

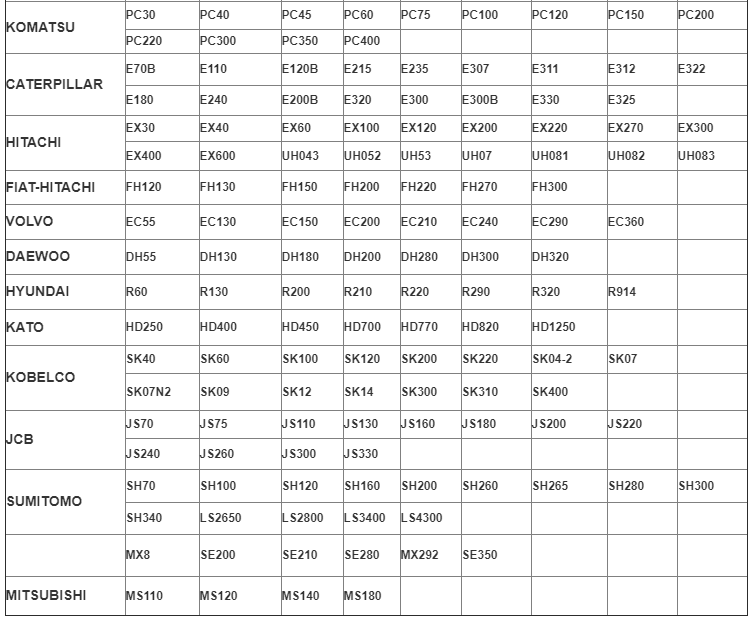

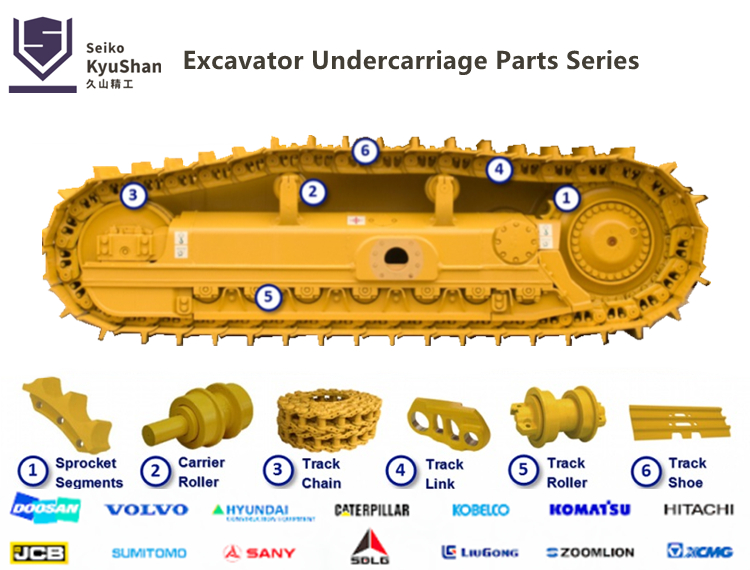

According to the size of the model and the usability of the industry and mine, the mini excavator sprockets can be made of materials:

G33MnCrMo, G33Mn4, SCMnCr4B, ZG35Mn, etc. After the normalizing heat treatment of the excavator sprocket blank, the matrix hardness reaches above HB235, and the driving tooth is hardened by medium frequency induction hardening and tempering at low temperature. The surface hardness reaches HRC48-54, and the hardening depth is above 5-10mm (HRC45). It can accurately transmit power under harsh working conditions, and has excellent anti-wear performance, which significantly improves product life and reduces customer use costs.

Factory Sales All Part Numbers Mini Excavator Sprockets For Sale

| Name | Best Seller High Quality Idler Hitachi Excavator Spare Parts |

| Product Number | All Part Numbers You Need |

| Condition | Original Brand New |

| MOQ | 1 Piece |

| Payment | T/T, Western Union, Paypal, etc |

| Standard or Nonstandard | Standard |

| Delivery Time | In 3 Days |

| Packing | Wooden Box |

| Warranty | 6 Months |

| Transport | By sea/air/express (DHL/FEDEX/TNT/UPS/EMS/City-line) |

Material | G33MnCrMo5, G33Mn4, SCMnCr4B, ZG40Mn, ZG35Mn |

Finish | Smooth |

Colors | yellow or black |

Technique | Forging & casting |

Surface Hardness | HRC48-54, deepth: 5mm-10mm |

Warranty time | 2000 hour (Normal life 4000hours ) |

FOB Price | FOB Xiamen USD 40-500/Piece |

MOQ | 1piece |

Delivery Time | Within 25 days after contract established |

Package | seaworthy packing or according to client requirement |

Payment Term | (1) T/T |

(2) Irrevocable letter of credit at sight. |

We are a comprehensive supplier of excavator accessories, if you have excavator accessories needs, please contact us, we will be glad to receive your inquiry!

Sales Manager:Liam Cheng Wechat/Whatsapp:+8616653175111