- Kyushan

- China

- 3-5 working days

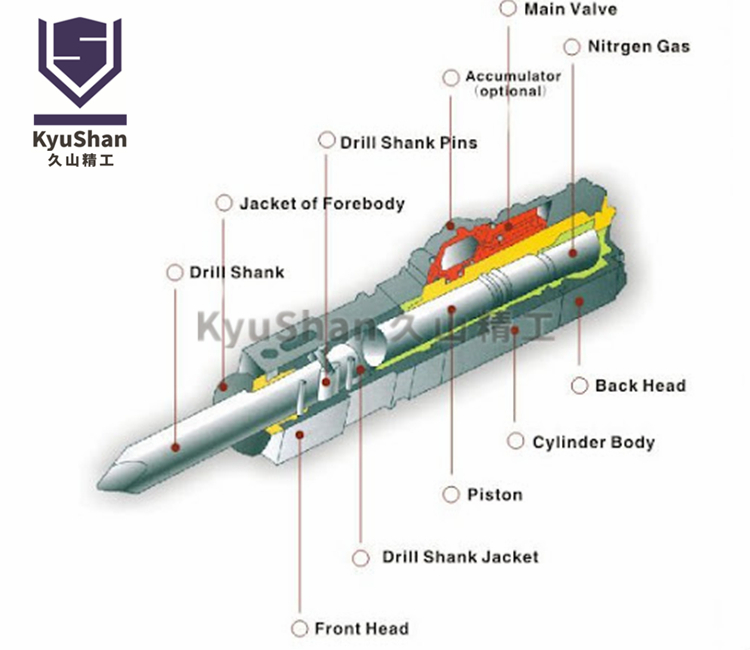

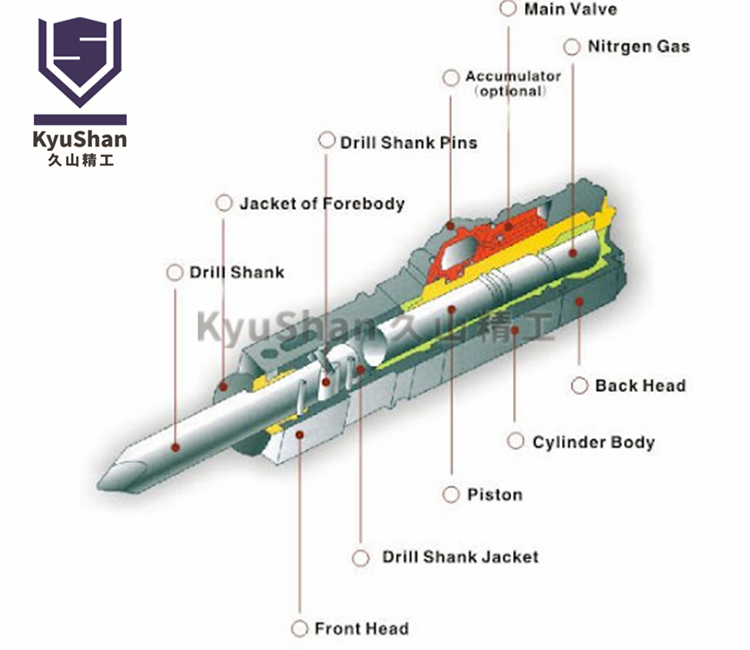

Application of hydraulic breakers for excavators:

1. Mining: mountain opening, mining, grid screen crushing, secondary crushing

2. Metallurgy: ladle, slag cleaning, furnace dismantling, equipment foundation dismantling

3. Railway: mountain driving, tunnel excavation, road and bridge demolition, roadbed consolidation

4. Highway: highway repair, cement pavement crushing, foundation excavation

5. Municipal gardens: concrete crushing, water, electricity, gas engineering construction, old city renovation

6. Construction: Demolition of old buildings, broken reinforced concrete

7. Ships: hull removal of mussels and rust

8. Others: ice breaking, frozen soil breaking, sand vibrating

All Sizes Hydraulic Breakers For Excavators

| Name | Hot Sales All Sizes Hydraulic Breakers For Excavators |

| Product Number | All Part Numbers You Need |

| Condition | Original Brand New |

| MOQ | 1 Piece |

| Payment | T/T, Western Union, Paypal, etc |

| Standard or Nonstandard | Standard |

| Delivery Time | In 3 Days |

| Packing | Wooden Box |

| Warranty | 6 Months |

| Transport | By sea/air/express (DHL/FEDEX/TNT/UPS/EMS/City-line) |

Correct use of hydraulic breaker:

1) Read the operation manual of the hydraulic breaker carefully to prevent damage to the hydraulic breaker and excavator, and operate them effectively.

2) Before operation, check whether the bolts and connectors are loose, and whether there is leakage in the hydraulic pipeline.

3) Do not peck holes in hard rock with a hydraulic breaker.

4) Do not operate the breaker when the piston rod of the hydraulic cylinder is fully extended or fully retracted.

5) When the hydraulic hose vibrates violently, stop the operation of the breaker and check the pressure of the accumulator.

6) Prevent interference between the boom of the excavator and the drill bit of the breaker.

7) Except for the drill bit, do not immerse the breaker in water.

8) Do not use the breaker as a lifting appliance.

9) Do not operate the breaker on the crawler side of the excavator.

10) When the hydraulic breaker is installed and connected to the hydraulic excavator or other construction machinery, the working pressure and flow rate of the hydraulic system of the main machine must meet the technical parameter requirements of the hydraulic breaker. The "P" port of the hydraulic breaker is connected to the high-pressure oil circuit of the main machine. Connection, "A" port is connected with the oil return circuit of the main engine.

11) The optimum hydraulic oil temperature when the hydraulic breaker is working is 50-60 degrees, and the maximum temperature should not exceed 80 degrees. Otherwise, the load of the hydraulic breaker should be reduced.

12) The working medium used by the hydraulic breaker can usually be consistent with the oil used in the hydraulic system of the main engine. It is recommended to use YB-N46 or YB-N68 anti-wear hydraulic oil in general areas, and YC-N46 or YC-N68 low temperature hydraulic oil in cold areas. Hydraulic oil filtration accuracy is not less than 50micro;m.

13) New and repaired hydraulic breakers must be recharged with nitrogen when they are in use, with a pressure of 2.5, ±0.5MPa.

14) Calcium-based grease or complex calcium-based grease must be lubricated between the shank of the drill rod and the guide sleeve of the cylinder body, and it must be refilled once per shift.

15) When the hydraulic breaker is working, the drill rod must be pressed on the rock first, and the breaker must be started after maintaining a certain pressure, and it is not allowed to start in the suspended state.

16) It is not allowed to use the hydraulic breaker as a crowbar to avoid breaking the drill rod.

17) The hydraulic breaker and fiber rod should be perpendicular to the working surface during use, and the principle of not generating radial force is the principle.

18) When the broken object has broken or started to crack, the impact of the breaker should be stopped immediately to avoid harmful "empty hitting".

19) If the hydraulic breaker is to be stopped for a long time, the nitrogen should be exhausted, and the oil inlet and outlet should be sealed. Do not store it in an environment of high temperature and -20 degrees.

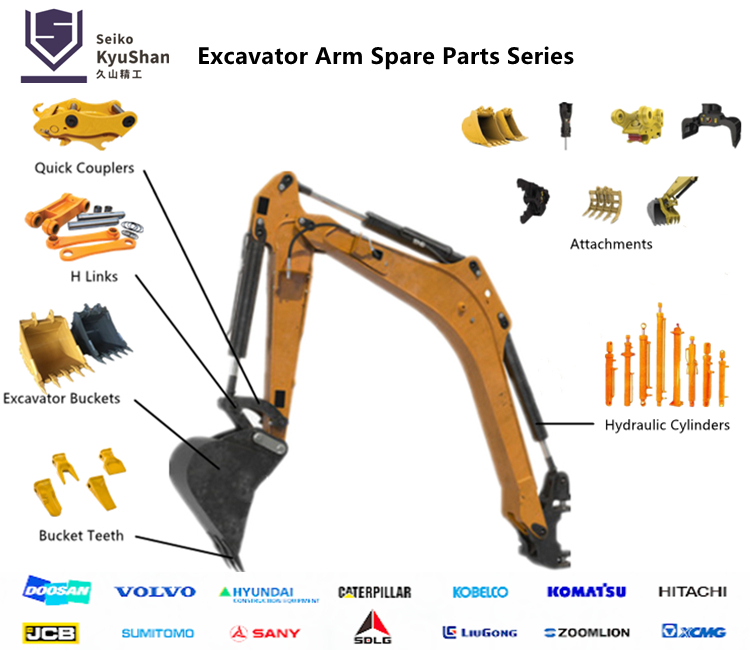

We are a comprehensive supplier of excavator accessories, if you have excavator accessories needs, please contact us, we will be glad to receive your inquiry!

Sales Manager:Liam Cheng Wechat/Whatsapp:+8616653175111