- Kyushan

- China

- 3-5 working days

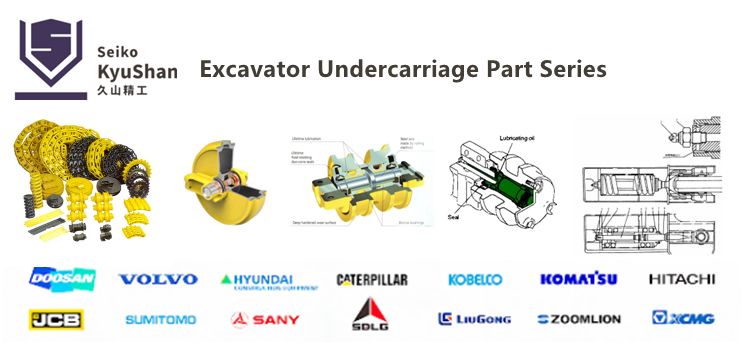

The carrier roller excavator, which is also called carrier roller or top roller, is one part of undercarriage parts for crawler heavy equipments such as excavator, bulldozer, crane, drilling machine etc.

Excavator carrier roller excavator is made of roller body, shaft, collars, Bi-metallic Bearings and seal group. It is made by forging, machining, heat treatment, assembly, painting etc.

The quality and working life depends on the quality of raw steels, the hardness of rail surface, the depth of hardness layer, the quality of seal group etc.

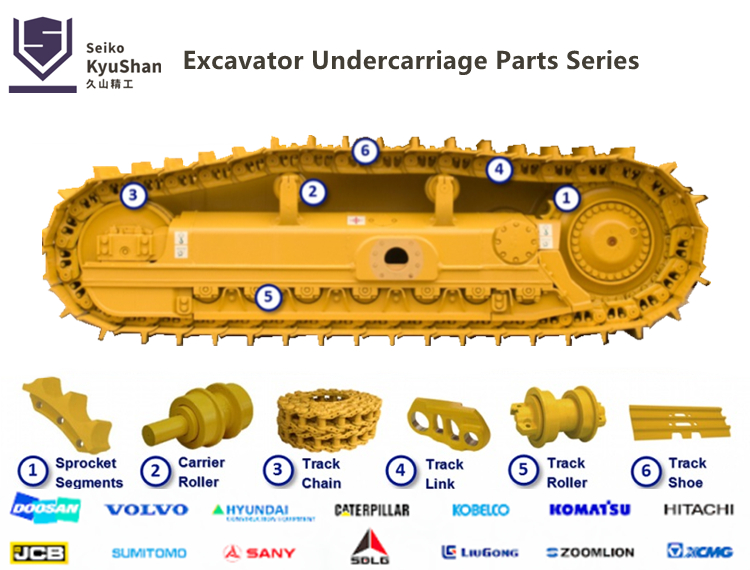

The carrier wheel is located above the X frame, and its function is to maintain the linear motion of the chain rail. If the carrier wheel is damaged, the track chain rail will not be able to maintain a straight line. The carrier wheel is a one-time injection of high-quality oil.

It can be replaced with a new one. During the work, try to avoid the rollers being soaked in muddy water for a long time. Usually, keep the X-frame inclined platform clean, and don't let too much dirt and gravel accumulate to hinder the rotation of the rollers.

Factory Direct Sales Carrier Roller Excavator Top Roller pc200 For Sale

| Name | Factory Direct Sales Carrier Roller Excavator Top Roller pc200 For Sale |

| Product Number | All Part Numbers You Need |

| Condition | Original Brand New |

| MOQ | 1 Piece |

| Payment | T/T, Western Union, Paypal, etc |

| Standard or Nonstandard | Standard |

| Delivery Time | In 3 Days |

| Packing | Wooden Box |

| Warranty | 6 Months |

| Transport | By sea/air/express (DHL/FEDEX/TNT/UPS/EMS/City-line) |

Material | 50Mn/40MnB |

Finish | Smooth |

Technique | Casting/Forging |

Surface Hardness | HRC50-58 , Depth:4mm-10mm |

Colors | Black or Yellow |

Warranty Time | 2000 Hours ( Normal life 4000 hours) |

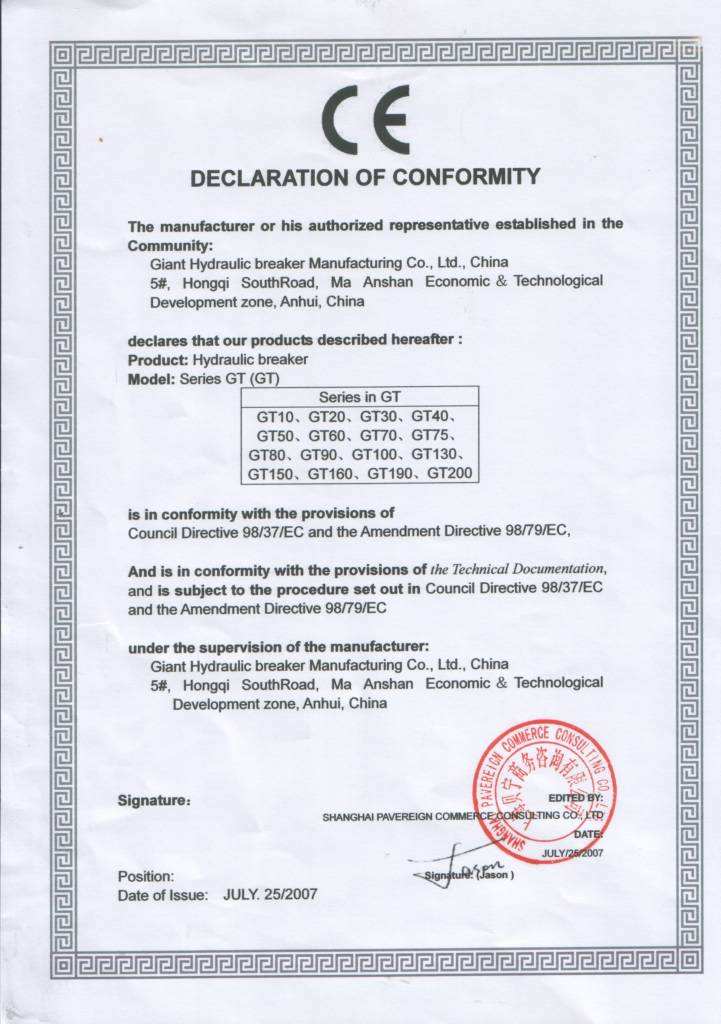

Certification | IS09001-9001 |

MOQ | 2 Pieces |

FOB Price | FOB Xiamen US$ 45-100/Piece |

Delivery Time | Within 30 days after contract established |

Payment Term | T/T,L/C,WESTERN UNION |

OEM/ODM | Acceptable |

Troubleshooting of excavator carrier roller

In order to make the fault inspection result accurate, disassembly inspection and maintenance will be carried out.

1. Remove the supporting wheel from the X frame support, open the outer end cover, and separate the rotating wheel body from the inner stator;

2. Remove the floating oil seal, clean up the corresponding positions of the wheel body and the stator with the floating oil seal, and be careful not to bring any oil traces;

3. Install a new floating oil seal, add butter, reassemble the wheel body and stator, and install the end cover;

4. Put the repaired sprocket back on the frame, and run it for about 5 minutes to make sure there is no more oil leakage.

We are a comprehensive supplier of excavator accessories, if you have excavator accessories needs, please contact us, we will be glad to receive your inquiry!

Sales Manager:Liam Cheng Wechat/Whatsapp:+8616653175111