- Kyushan

- China

- 3-5 working days

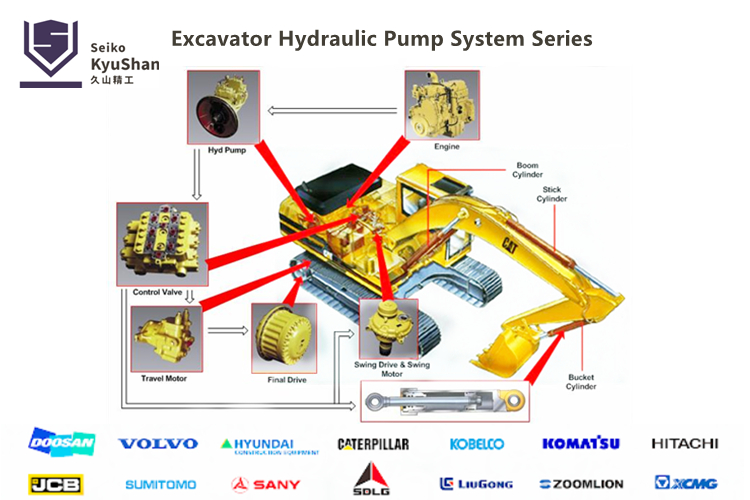

The cat 320d slewing motor is the key component of the excavator slewing mechanism. Motor swing cat 320d converts the oil pressure provided by the main pump into mechanical energy and inputs it to the reducer; cat 320d swing motor working performance will directly affect the slewing speed, driving torque, slewing speed of the whole machine. Parking and parking brakes are the keys to determining the productivity of the entire machine.

After the excavator works for a long time, the rotary motor often has the phenomenon of weak rotation and unstable rotation. At this time, it is necessary to replace the internal parts according to the test results.

Caterpillar Cat 320d Swing Motor

| Name | Best Seller Cheaper Caterpillar Cat 320d Swing Motor For Sale |

| Product Number | All Part Numbers You Need |

| Condition | Original Brand New |

| MOQ | 1 Piece |

| Payment | T/T, Western Union, Paypal, etc |

| Standard or Nonstandard | Standard |

| Delivery Time | In 3 Days |

| Packing | Wooden Box |

| Warranty | 6 Months |

| Transport | By sea/air/express (DHL/FEDEX/TNT/UPS/EMS/City-line) |

Disassembly steps of cat 320d swing motor:

1. Choose a relatively clean and large area of operation, and lay a rubber sheet or a thick cloth on the workbench to prevent knock marks on the parts when they are touched.

2. Use cleaning oil to remove garbage, oil stains, rust, etc. on the surface.

3. Lay sleepers on the workbench in advance, place the shaft end of the drive shaft down and place it vertically on the sleepers.

4. Mark the joint between the housing and the valve body.

5. Use a wrench to loosen the relief valve and remove it from the valve body.

6. Use a 24mm Torx wrench to loosen the anti-reverse valve and take it out from the valve body.

7. Use a 6mm hex wrench to remove the anti-reverse valve body.

8. Use a 14mm hexagon wrench to remove the plug from the valve body, and remove the spring and check valve; at this time, be sure to pay attention to the manual operation when removing the internal parts.

9. Use a 14mm hexagon wrench to loosen the hexagon bolts of the valve housing. At this time, due to the elastic force of the brake spring, the angle should be gradually loosened when loosening the hexagon bolts. After the bolts are loosened, the valve body will automatically float from the housing.

10. Take the valve plate and brake spring out of the valve body.

11. Use the brake piston pulling tool to pull the brake piston vertically upward from the housing; at this time, pay attention to hook the claw tip of the special tool to the concave part of the brake piston.

12. Place the rotary motor horizontally on the workbench, take out the friction plate and spacer plate from the casing, and take out the cylinder block, piston and swash plate in turn from the transmission shaft. Because the plunger and the cylinder are in one-to-one correspondence, they can be marked when they are taken out to match the cylinder when they are installed. At this time, be careful not to bump or scratch them.

13. Use circlip pliers to take out the fixed circlip of the drive shaft, and tap the drive shaft with a shock-absorbing hammer to pull it out from the housing.

We are a comprehensive supplier of excavator accessories, if you have excavator accessories needs, please contact us, we will be glad to receive your inquiry!

Sales Manager:Liam Cheng Wechat/Whatsapp:+8616653175111