- Kyushan

- China

- 3-5 working days

How to maintain the bobcat 331 track?

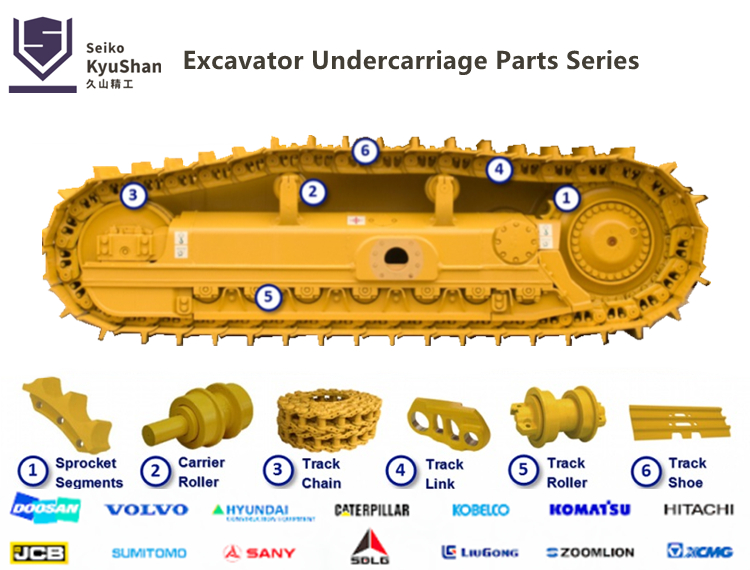

1. The sprocket should be installed on the shaft without skewing and swinging. The end faces of the two sprockets in the same transmission assembly should be in the same plane. When the center distance of the sprockets is less than 0.5m, the allowable deviation is 1mm, and the center distance of the sprockets is 1mm. When it is larger than 0.5m, the allowable deviation is 2mm, but the tooth surface of the sprocket is not allowed to be rubbed. If the deviation of the two wheels is too large, it is easy to cause the chain to separate and accelerate the wear. When replacing the sprocket, pay attention to checking and adjusting the deviation.

2. The tightness of the bobcat 331 track chain should be appropriate, too tight will increase the power consumption, and the bearing will be easily worn; the chain that is too loose is easy to jump off, the tightness of the chain is: lift or press from the middle of the chain, and the center distance between the two sprockets is about 2-3 centimeter.

Factory Direct Sale Bobcat 331 Track For Excavator

| Name | Factory Direct Sale Bobcat 331 Track For Excavator |

| Product Number | All Part Numbers You Need |

| Condition | Original Brand New |

| MOQ | 1 Piece |

| Payment | T/T, Western Union, Paypal, etc |

| Standard or Nonstandard | Standard |

| Delivery Time | In 3 Days |

| Packing | Wooden Box |

| Warranty | 6 Months |

| Transport | By sea/air/express (DHL/FEDEX/TNT/UPS/EMS/City-line) |

3. If the new bobcat 331 track is too long or stretched after use, it is difficult to adjust, if necessary, remove the link, but it must be flat, the link should go through the back of the chain, the cleat should be inserted outside, the opening of the cleat Should face the opposite direction of rotation.

4. When the sprocket is severely worn, the new sprocket and the new chain should be replaced at the same time to ensure good meshing. Only the new chain or the new sprocket cannot be replaced alone, otherwise it will cause poor meshing and accelerate the wear of the new chain or sprocket. When the tooth surface is worn to a certain extent, it should be turned over in time (referring to the sprocket with adjustable surface), so as to prolong the service time.

5. The old chain cannot be mixed with some new chains, otherwise it is easy to impact the transmission and break the chain.

6. The chain should be filled with lubricating oil in time when working, and the lubricating oil must enter the gap between the roller and the inner sleeve to improve working conditions and reduce wear.

7. When the machine is stored for a long time, the chain should be removed and washed with kerosene or diesel oil, then coated with oil or butter, and stored in a dry place to prevent corrosion.

We are a comprehensive supplier of excavator accessories, if you have excavator accessories needs, please contact us, we will be glad to receive your inquiry!

Sales Manager:Liam Cheng Wechat/Whatsapp:+8616653175111