- Kyushan

- China

- 3-5 working days

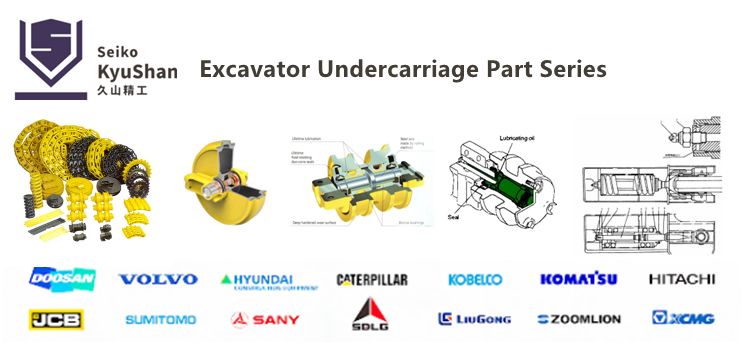

The idler pc200, which is also called idler group, idler assy, front idler or idler wheel, is one part of undercarriage parts for crawler heavy equipments such as excavator, bulldozer, crane, drilling machine etc.

The idler pc200 is made of idler shell, shaft, brackets, Bi-metallic Bearings and seal group. It is made by casting or forging, machining, heat treatment, assembly, painting etc.

The quality and working life depends on the quality of raw steels, the hardness of rail surface, the depth of hardness layer, the quality of seal group etc.

The misalignment of the idler excavator has a serious impact on other parts of the walking mechanism, so we need to adjust the gap between the guide wheel guide plate and the track frame to achieve the purpose of extending the life of the walking mechanism. When adjusting the gap, pay attention to use the gasket between the guide plate and the bearing to correct it. If the gap is large, remove the gasket; if the gap is small, add a gasket.

Idler pc200 Excavator For Komatsu

| Name | Idler pc200 Excavator For Komatsu |

| Product Number | All Part Numbers You Need |

| Condition | Original Brand New |

| MOQ | 1 Piece |

| Payment | T/T, Western Union, Paypal, etc |

| Standard or Nonstandard | Standard |

| Delivery Time | In 3 Days |

| Packing | Wooden Box |

| Warranty | 6 Months |

| Transport | By sea/air/express (DHL/FEDEX/TNT/UPS/EMS/City-line) |

Material | 50Mn/40MnB |

Finish | Smooth |

Technique | Casting/Forging |

Surface Hardness | HRC50-56 , Deepth:4mm-10mm |

Colors | Black or Yellow |

Warranty Time | 2000 Hours ( Normal life 4000 hours) |

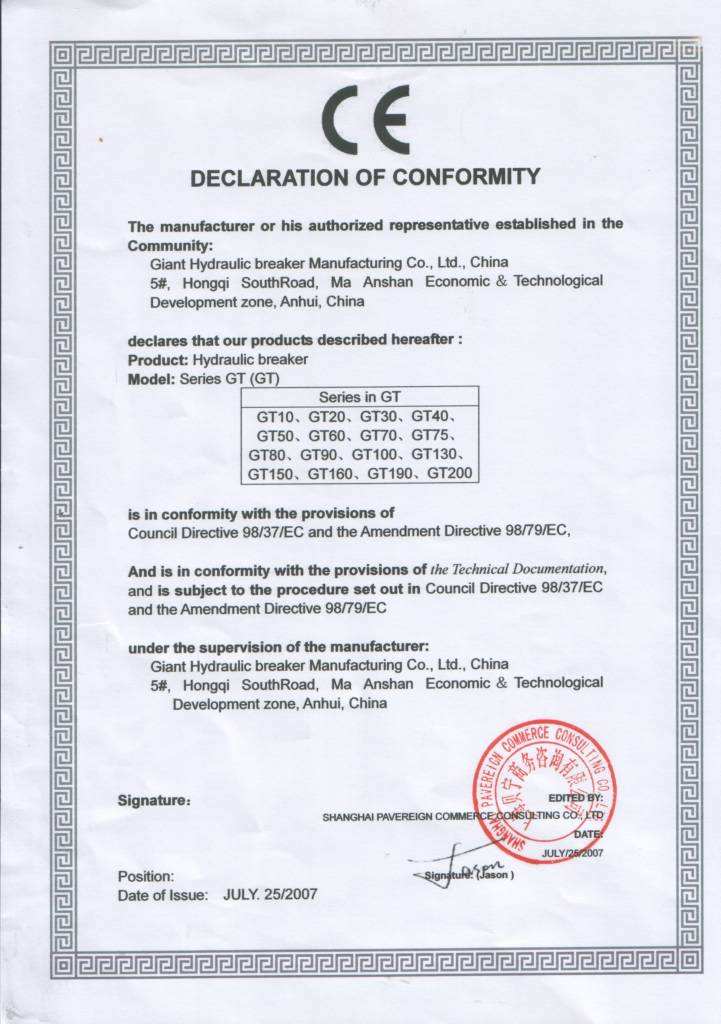

Certification | IS09001-9001 |

MOQ | 2 Pieces |

FOB Price | FOB Xiamen US$ 80-150/Piece |

Delivery Time | Within 30 days after contract established |

Payment Term | T/T,L/C,WESTERN UNION |

OEM/ODM | Acceptable |

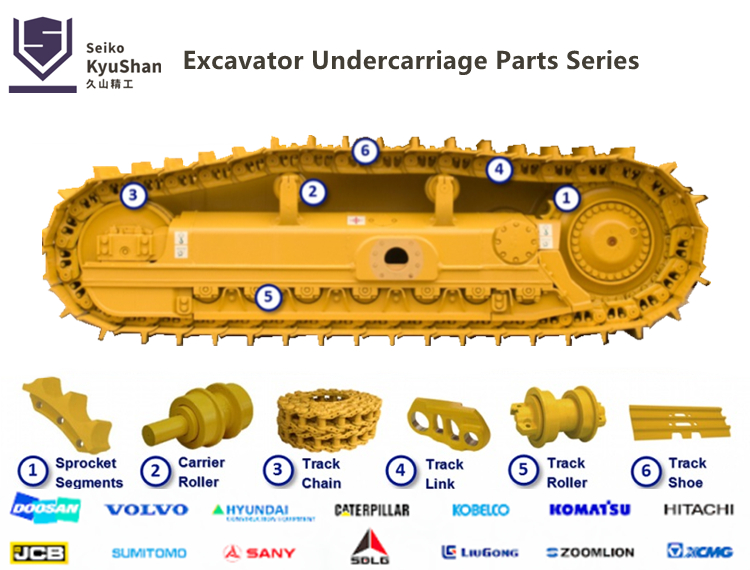

Excavator Idler Product Introduction

The excavator idler is used to guide the crawler to rotate correctly and prevent it from running off track and deviating from the track. Most excavators also function as rollers. This can increase the contact area of the track to the ground and reduce the ground specific pressure. The wheel surface of the guide wheel is made of smooth surface, and there is a retaining arm ring in the middle as a guiding function, and the ring surfaces on both sides support the rail chain.

Excavator idler key points

In order to make the excavator guide wheel work and prolong its life, the radial runout of the wheel facing the center hole should be less than or equal to 3MM, and it should be correctly centered during installation.

Excavator idler process characteristics

The excavator idler body adopts a box-type structure cast by resin sand technology, with reasonable mechanical structural properties; the matrix is normalized to obtain good impact resistance; and the rail surface is subjected to medium frequency induction quenching heat treatment, and the surface hardness reaches HRC48-54, 6mm The depth is not lower than HRC46. It has wear resistance under harsh working conditions.

We are a comprehensive supplier of excavator accessories, if you have excavator accessories needs, please contact us, we will be glad to receive your inquiry!

Sales Manager:Liam Cheng Wechat/Whatsapp:+8616653175111