- Kyushan

- China

- 3-5 working days

Main Features of kubota track rollers:

1.Single and double-edge road wheel suits for Kubota excavating machine and special machinery ranging 3 to 50 tons.

2.Double conical sealing and lifelong lubrication design enable the road wheel to have longer service life and perfect performance in any circumstances.

3.The shell of kubota track rollers made by hot forging treatment obtains superior structure of internal materials and fiber.

4.Differential quenching or feed-through quenching heat treatment is effective in crack resistance.

All Kinds Of Kubota Track Rollers Excavator Spare Parts For Sale

| Name | All Kinds Of Kubota Track Rollers Excavator Spare Parts For Sale |

| Product Number | All Part Numbers You Need |

| Condition | Original Brand New |

| MOQ | 1 Piece |

| Payment | T/T, Western Union, Paypal, etc |

| Standard or Nonstandard | Standard |

| Delivery Time | In 3 Days |

| Packing | Wooden Box |

| Warranty | 6 Months |

| Transport | By sea/air/express (DHL/FEDEX/TNT/UPS/EMS/City-line) |

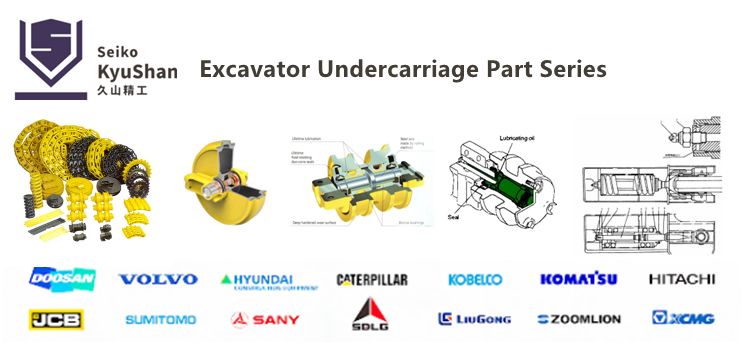

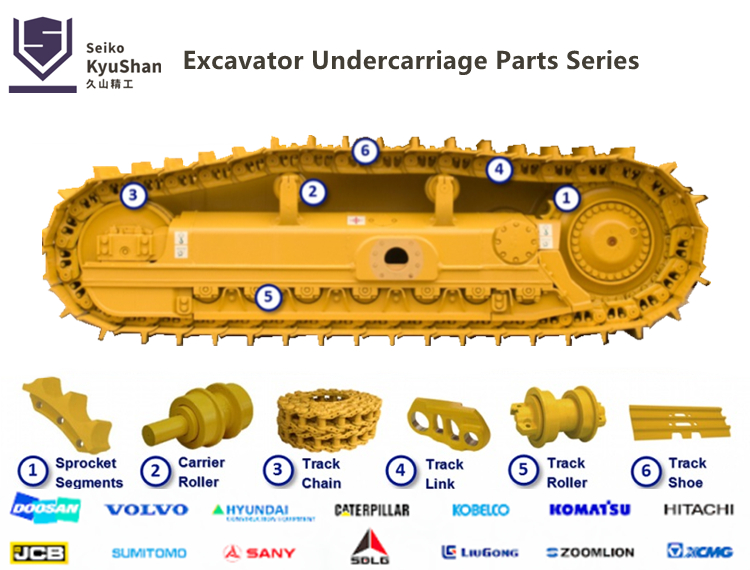

Track Roller, Bottom Roller & Lower Roller For Excavators & Bulldozers

Kyushan specializes in manufacturing high quality undercarriage parts for mining area with one year guarantee. We worked in this area over 10 years. Our rollers are designed and manufactured to provide outstanding service under extreme working conditions.

Faults that are prone to occur in track roller excavator:

(1) The wheel body is worn. The reason for this is that the steel used is unqualified or the hardness of the material during heat treatment is low and the wear resistance is insufficient;

(2) Oil leakage. The roller shaft is constantly rotating through the shaft sleeve, and the wheel body needs to be lubricated with oil, but if the sealing ring is not good, it is easy to cause oil leakage, so the shaft and the shaft sleeve are easy to wear without lubrication. cause the product to be unusable. The reasons for oil leakage are as follows: 1. Unqualified floating oil seal; 2. Insufficient roundness of product shaft sleeve; 3. Insufficient gloss of fulcrum; 4. Gear oil not up to standard; 5. Machining dimensional tolerance, etc. All of the above problems will cause the oil leakage of the rollers.

We are a comprehensive supplier of excavator accessories, if you have excavator accessories needs, please contact us, we will be glad to receive your inquiry!

Sales Manager:Liam Cheng Wechat/Whatsapp:+8616653175111