- Kyushan

- China

- 3-5 working days

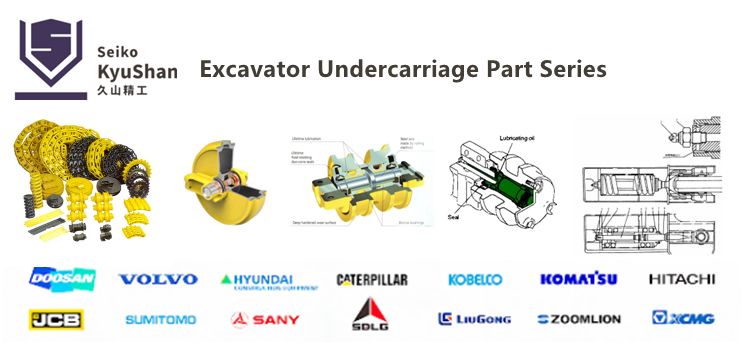

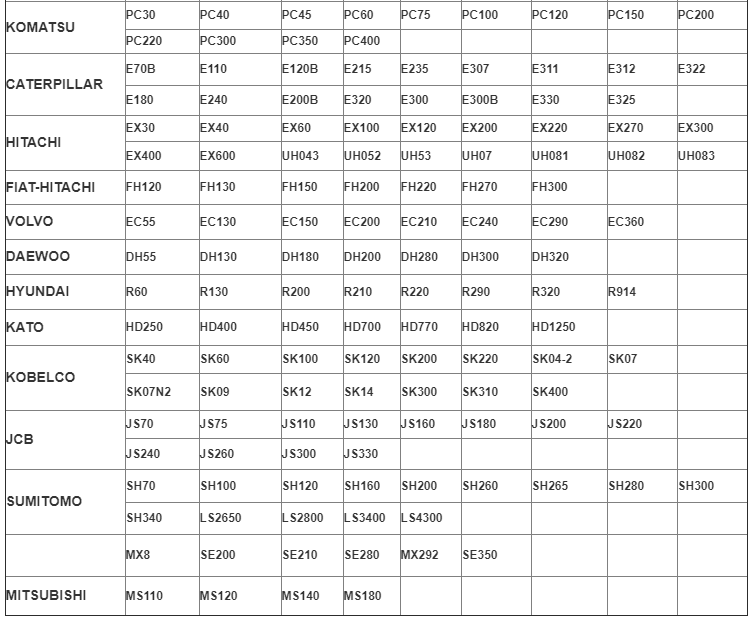

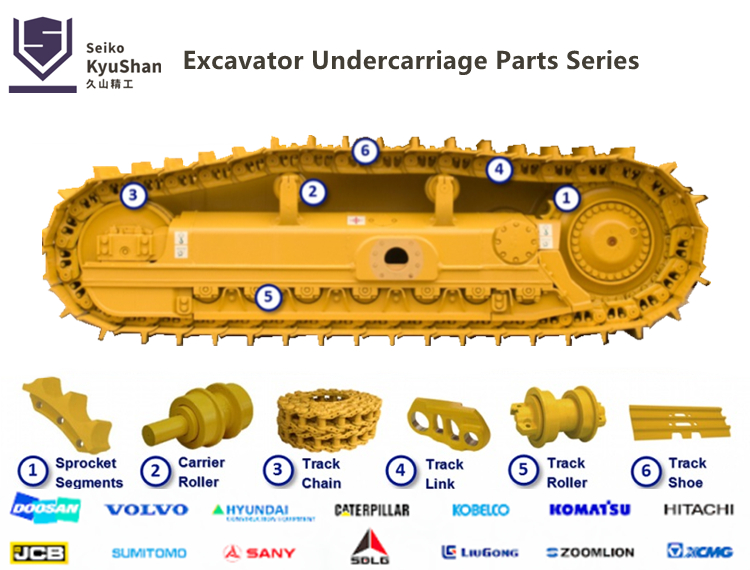

The pc200 sprocket wheel, is one part of undercarriage parts for crawler heavy equipments such as excavator, bulldozer, crane, drilling machine etc.

The pc200 sprocket wheel is made by casting, machining, heat treatment, painting etc.The pc200 sprocket wheel is made by casting, machining, heat treatment, painting etc.

The quality and working life depends on the quality of casting steel, the hardness of rail surface, the depth of hardness layer etc.

The shape of the sprocket pc200 is toothed. When the excavator digs the ground, the stress of the traveling device is relatively large. In addition to the pressure caused by the rotation and twisting of the car body, the toothed sprocket pc200 is in the front, which can play a relatively stable mobility.

Sprocket pc200 Excavator Spare Parts

| Name | High Quality Cheaper Sprocket pc200 Excavator Spare Parts |

| Product Number | All Part Numbers You Need |

| Condition | Original Brand New |

| MOQ | 1 Piece |

| Payment | T/T, Western Union, Paypal, etc |

| Standard or Nonstandard | Standard |

| Delivery Time | In 3 Days |

| Packing | Wooden Box |

| Warranty | 6 Months |

| Transport | By sea/air/express (DHL/FEDEX/TNT/UPS/EMS/City-line) |

Material | 40SiMnTi |

Finish | Smooth |

Technique | Casting/Forging |

Surface Hardness | HRC50-56 , Deepth:4mm-10mm |

Colors | Black or Yellow |

Warranty Time | 2000 Hours ( Normal life 4000 hours) |

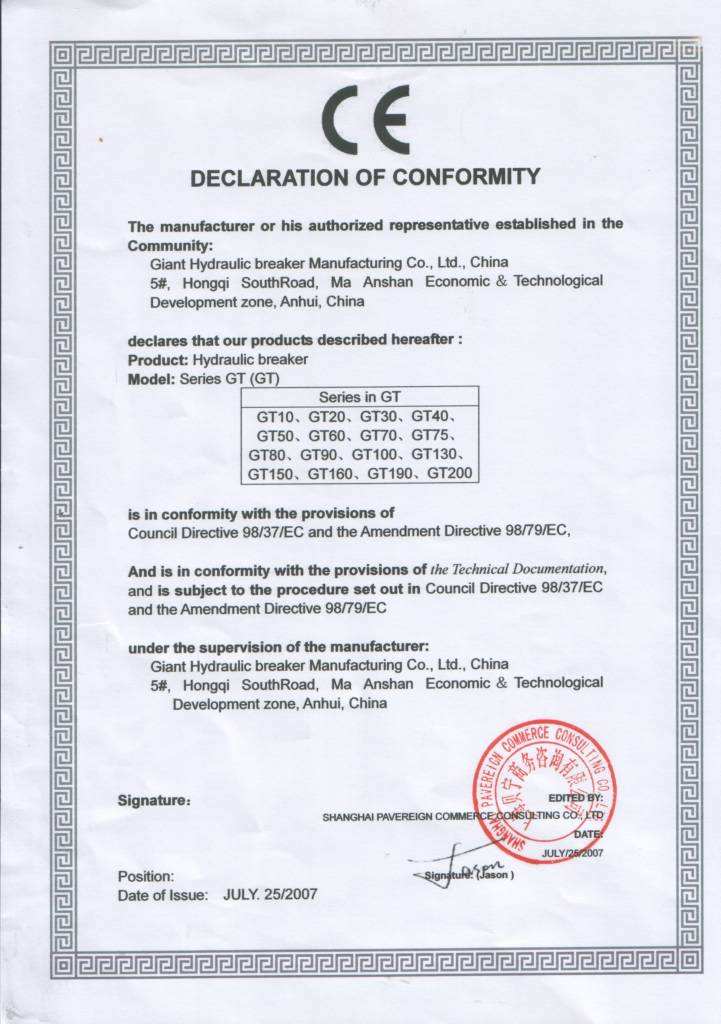

Certification | IS09001-9001 |

MOQ | 2 Pieces |

FOB Price | FOB Xiamen US$80-100/Piece |

Delivery Time | Within 30 days after contract established |

Payment Term | T/T,L/C,WESTERN UNION |

OEM/ODM | Acceptable |

When rotating, it will not slide out of the track easily, preventing the track from deviating. The drive wheel is used to transmit the power of the walking motor to the track and drive the track to roll forward. Therefore, the main requirement of the sprocket pc200 is to engage smoothly and maintain good condition when the track is stretched due to wear of the pin bushing.

The power of the hydraulic crawler mechanical engine is transmitted to the crawler through the traveling motor and the excavator sprocket, which requires the sprocket and the track chain of the crawler to engage correctly, the transmission is smooth, and the crawler can still mesh well when the track is stretched due to wear of the pin sleeve.

The excavator sprockets produced by Kyushan have the following characteristics:

uniform casting

Precision Machining

Deep hardened profiles

Reduce downtime

Reduce maintenance costs

Induction hardening

We are a comprehensive supplier of excavator accessories, if you have excavator accessories needs, please contact us, we will be glad to receive your inquiry!

Sales Manager:Liam Cheng Wechat/Whatsapp:+8616653175111