- Kyushan

- China

- 3-5 working days

1.The track shoe pc200 is through quench-tempering processes to guarantee excellent mechanical properties, high strength and superior wear resistence to bending and breakage.

2.The surface hardness of the track group with shoes is HRC50-60 for reduced wear and longer life, adding value to your products further to your business by maximizing durability of your products.

3. track shoe pc200 have precise design, carefully manufactured for proper fix easy grousering heavy loaded capacity up to 50tons without compromising proper functioning of the excavators reliable quality, high cost performance,quality services.Our products,your best choice.

Commonly track shoes are divided into three types according to the grounding shape, including single-rib, three-rib and flat bottom, and some of them also use triangular track shoes. The single-reinforced track shoes are mainly used for bulldozers and tractors, because the track shoes are required to have high traction capacity when such machinery works.

Track Shoe pc200 For Komatsu Excavator

| Name | Factory Sales Cheaper Track Shoe pc200 For Komatsu Excavator |

| Product Number | All Part Numbers You Need |

| Condition | Original Brand New |

| MOQ | 1 Piece |

| Payment | T/T, Western Union, Paypal, etc |

| Standard or Nonstandard | Standard |

| Delivery Time | In 3 Days |

| Packing | Wooden Box |

| Warranty | 6 Months |

| Transport | By sea/air/express (DHL/FEDEX/TNT/UPS/EMS/City-line) |

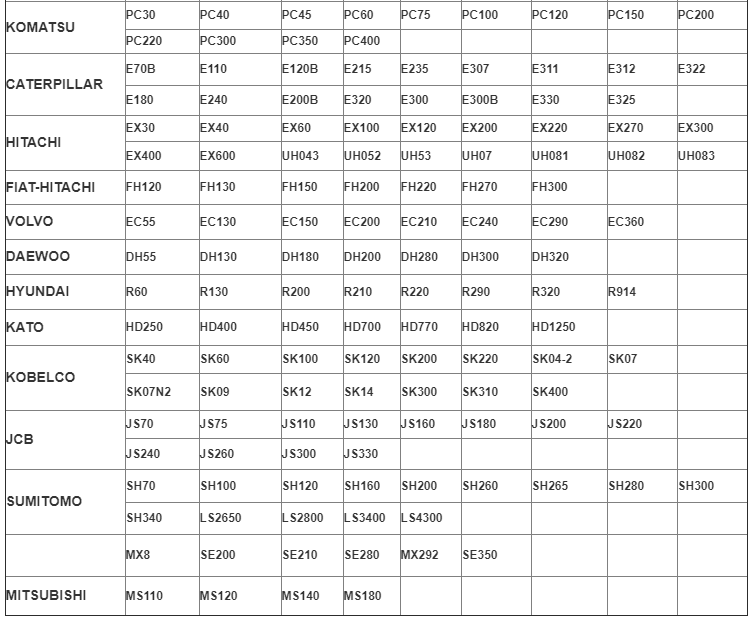

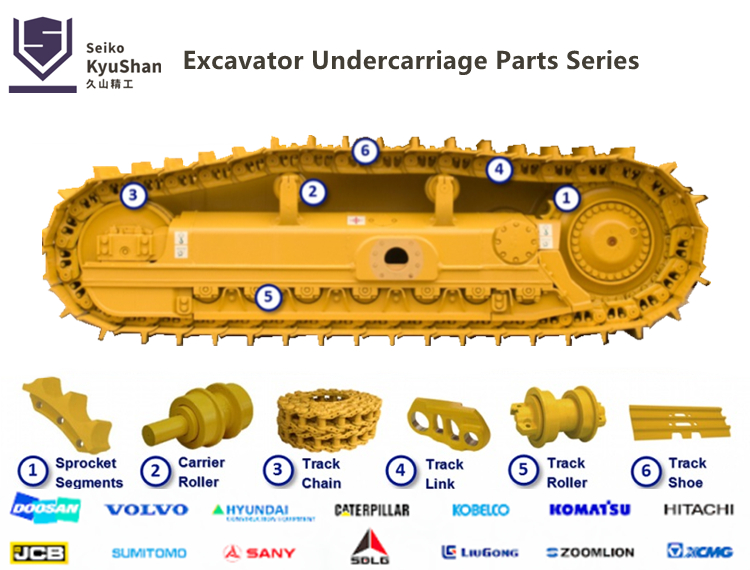

track shoe pc200 , which is also called track shoe plate, ttrack shoe assy, is one part of undercarriage parts for crawler heavy equipments such as excavator, bulldozer, crane, drilling machine etc.

Excavator track group with shoes is made by rolling, machining, heat treatment, painting etc.

The quality and working life depends on the quality of rolled steel, the hardness of hardening and tempering, the depth of hardness lay.

The wear of the track shoe mainly has two parts: the raceway surface and the track pin hole. It is very simple to repair. After the raceway is worn, a groove sags, and when the depth does not exceed 2~3 mm, it can be directly repaired by surfacing welding.

When the wear is deep, steel bars of different sizes can be filled in the grooves according to the specific conditions, and then welded from all sides. The pin hole should be restored to the original size and the center position of the original hole after grinding.

For this purpose, cut the worn pin hole, insert a standard size pin, then heat it to about 800 ℃, and then roll up the edge of the ear. Add a semi-circular iron plate to the outside of the incision and weld it firmly with electric welding. The track shoes thus repaired can last for more than 100 shifts

| Material | 40Mn/40SiMnTi |

| Finish | Smooth |

| Technique | Casting/Forging |

| Surface Hardness | HRC50-56 , Depth:4mm-10mm |

| Colors | Black or Yellow |

| Warranty Time | 2000 Hours ( Normal life 4000 hours) |

| Certification | IS09001-9001 |

| MOQ | 2 Pieces |

| FOB Price | FOB Xiamen US$ 100-500/Piece |

| Delivery Time | Within 30 days after contract established |

| Payment Term | T/T,L/C,WESTERN UNION |

| OEM/ODM | Acceptable |

We are a comprehensive supplier of excavator accessories, if you have excavator accessories needs, please contact us, we will be glad to receive your inquiry!

Sales Manager:Liam Cheng Wechat/Whatsapp:+8616653175111