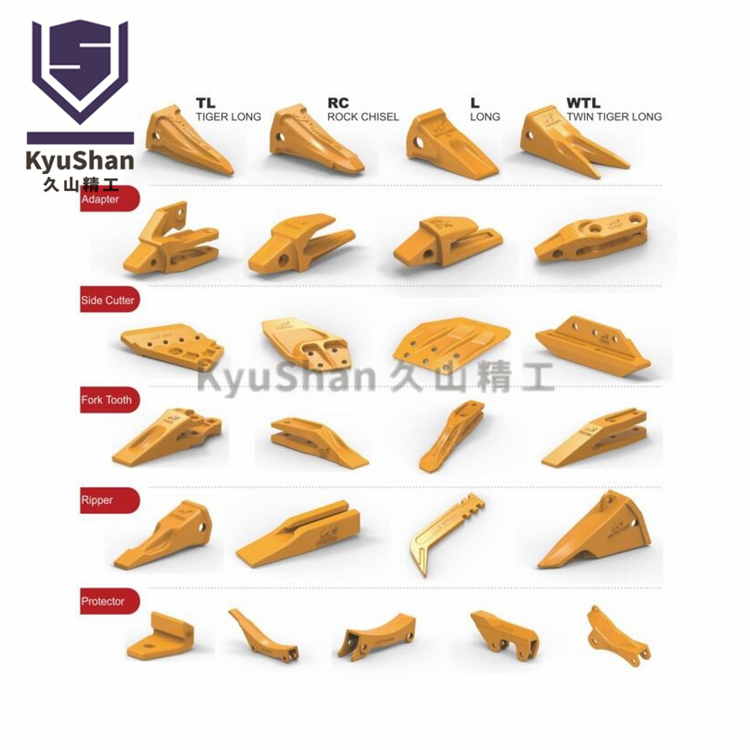

- Kyushan

- China

- 3-5 working days

Cat excavator teeth replacement cycle:

The replacement cycle of the cat excavator teeth should be determined according to the construction environment and the degree of wear of the bucket teeth. For example, the excavator has been doing earthwork work, so the wear degree of the cat excavator teeth is relatively small, and it is generally replaced every 4-5 months. .

If it is a rock-type cat excavator teeth, the frequency of replacing the bucket teeth is faster. Like granite, it takes about a week to replace the bucket teeth. Of course, this cycle is not fixed, and it depends on the quality of the bucket teeth and the meticulousness of the actual operation. and so on to determine the replacement frequency of bucket teeth.

Caterpillar Cat Excavator Bucket Teeth Replacement For Sale

| Name | Caterpillar Cat Excavator Bucket Teeth Replacement For Sale |

| Product Number | All Part Numbers You Need |

| Condition | Original Brand New |

| MOQ | 1 Piece |

| Payment | T/T, Western Union, Paypal, etc |

| Standard or Nonstandard | Standard |

| Delivery Time | In 3 Days |

| Packing | Wooden Box |

| Warranty | 6 Months |

| Transport | By sea/air/express (DHL/FEDEX/TNT/UPS/EMS/City-line) |

Caterpillar excavator teeth:

1. Keep it sharp: the caterpillar excavator teeth on both sides of the excavator generally wear about 30% faster than the caterpillar excavator teeth in the middle of the bucket. Change the position and continue to use it, which indirectly increases the service life of the bucket teeth.

Tips: If the difference between the central part of the bucket teeth and the two ends of the bucket teeth is 2~3cm, it can be exchanged.

2. Pay attention to the angle of digging operation: when the caterpillar excavator teeth are digging down, it is perpendicular to the working surface, so as to avoid breaking the bucket teeth due to the excessive inclination angle.

3. Wear of the tooth seat: It is recommended to replace the tooth seat when the tooth seat is worn out by 10-15%. There is a large gap between the tooth seat and the bucket teeth with excessive wear, so that the cooperation between the bucket teeth and the tooth seat And the force point changes, causing the bucket teeth to break due to the change of the force point.

4. Driving method: try not to retract the bucket when lifting the boom, and pay special attention to the coordination of actions. Some excavator drivers often throw the bucket on the rock with too much force during the action of enlarging the arm and sending the forearm, which will smash or crack the bucket teeth and damage the forearm.

We are a comprehensive supplier of excavator accessories, if you have excavator accessories needs, please contact us, we will be glad to receive your inquiry!

Sales Manager:Liam Cheng Wechat/Whatsapp:+8616653175111