- Kyushan

- China

- 3-5 working days

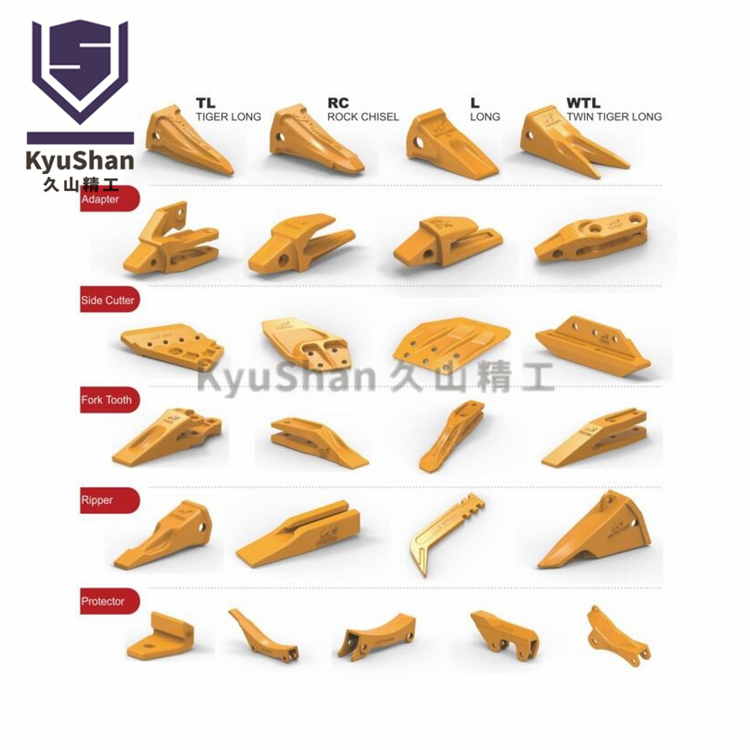

Buying Guide of komatsu pc200 bucket teeth:

If your excavator is doing earthwork, the frequency and demand for replacing komatsu pc200 bucket teeth every year is relatively small, then it is recommended that you choose forging and casting komatsu pc200 bucket teeth, although the price is much higher, but the service life, production process and quality are all is optimal.

If the requirement for the number of bucket teeth is relatively large, then the cost performance of the komatsu pc200 bucket teeth is required to be relatively high, then the precision cast bucket teeth perform well in terms of price, quality, cost performance and wear resistance.

Cheaper Best Quality Komatsu pc200 Bucket Teeth For Sale

| Name | Cheaper Best Quality Komatsu pc200 Bucket Teeth For Sale |

| Product Number | All Part Numbers You Need |

| Condition | Original Brand New |

| MOQ | 1 Piece |

| Payment | T/T, Western Union, Paypal, etc |

| Standard or Nonstandard | Standard |

| Delivery Time | In 3 Days |

| Packing | Wooden Box |

| Warranty | 6 Months |

| Transport | By sea/air/express (DHL/FEDEX/TNT/UPS/EMS/City-line) |

To put it simply, the komatsu pc200 bucket teeth are selected according to the working conditions. The place to save money can be saved, and the right ones are not expensive! But if it is required by the working conditions, then the komatsu pc200 bucket teeth of the expensive, hard material and big brands, although The initial investment is large, and the return you can receive is also leveraged!

In other words, if it is just for saving money and making a cheap price, the purchased bucket teeth will definitely be greatly discounted in terms of engineering work and service life. When you look back, you will regret it, I am afraid that the money in your wallet will be wasted!

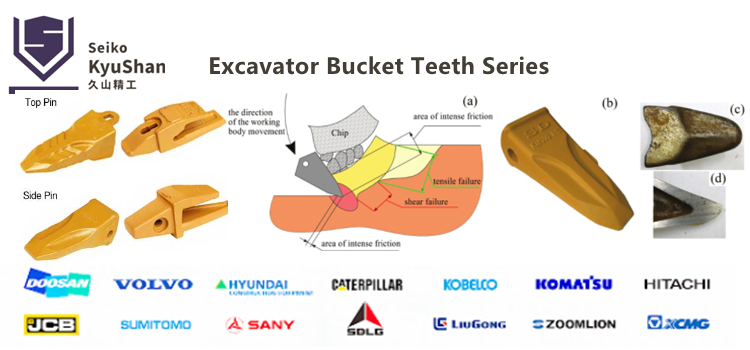

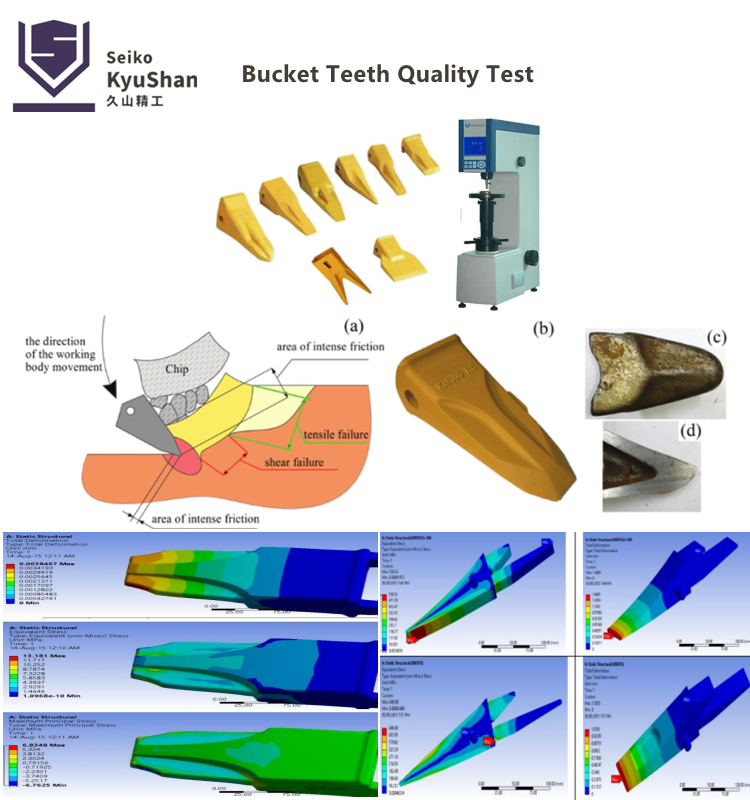

The technological process of bucket teeth: sand casting, forging and precision casting.

Sand casting: The cost is the lowest, and the technology level and the quality of the bucket teeth are not as good as precision casting and forging casting.

Forging: The cost is the highest and the craftsmanship and the quality of the bucket teeth are also the best.

Precision casting: The cost is moderate but the requirements for raw materials are very strict, and the technology level is relatively high. Due to the ingredients, some of the precision casting bucket teeth have even higher wear resistance and quality than forging and die casting bucket teeth. At present, precision casting bucket teeth is the mainstream manufacturing process for bucket teeth on the market.

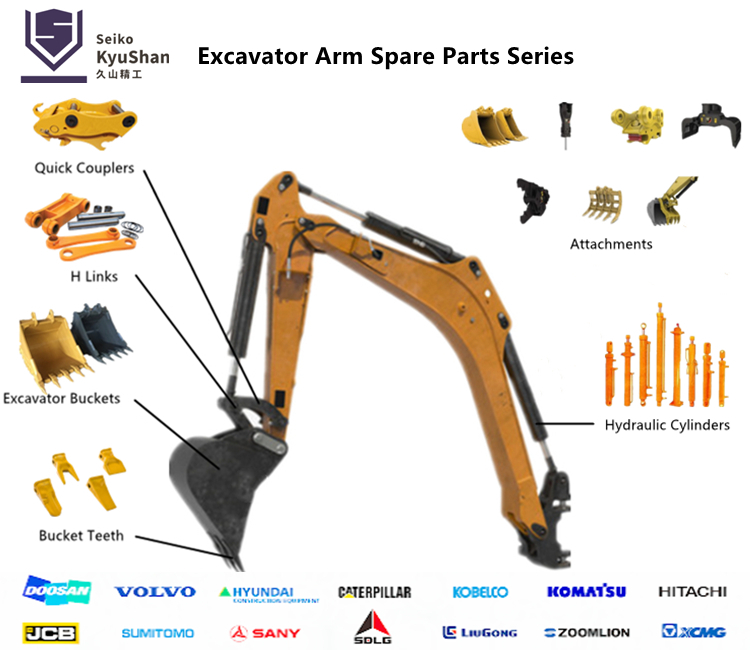

We are a comprehensive supplier of excavator accessories, if you have excavator accessories needs, please contact us, we will be glad to receive your inquiry!

Sales Manager:Liam Cheng Wechat/Whatsapp:+8616653175111