- Kyushan

- China

- 3-5 working days

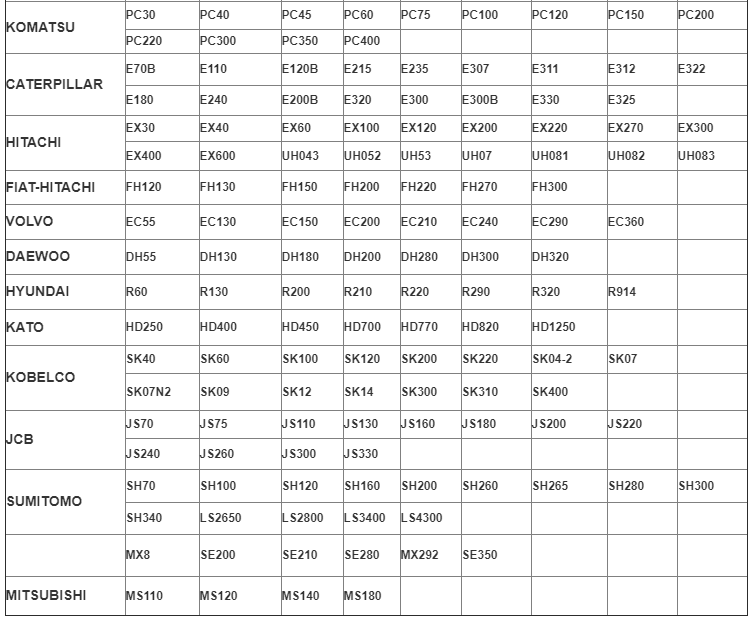

1. During the use of the komatsu bucket teeth of the excavator, the outermost teeth of the bucket wear 30% faster than the innermost teeth. After a period of use, the inner and outer komatsu bucket teeth of the bucket should be replaced.

2. The excavator driver should pay attention to the angle of digging during the operation, try to master it when digging, and the komatsu bucket teeth are perpendicular to the working face when digging down, so as to avoid breaking the bucket teeth due to excessive inclination.

3. Be careful not to swing the digging arm left and right under the condition of large resistance, so that the komatsu bucket teeth and tooth adapter are easily broken due to excessive force on the left and right sides, and the design of the force on the left and right is not considered.

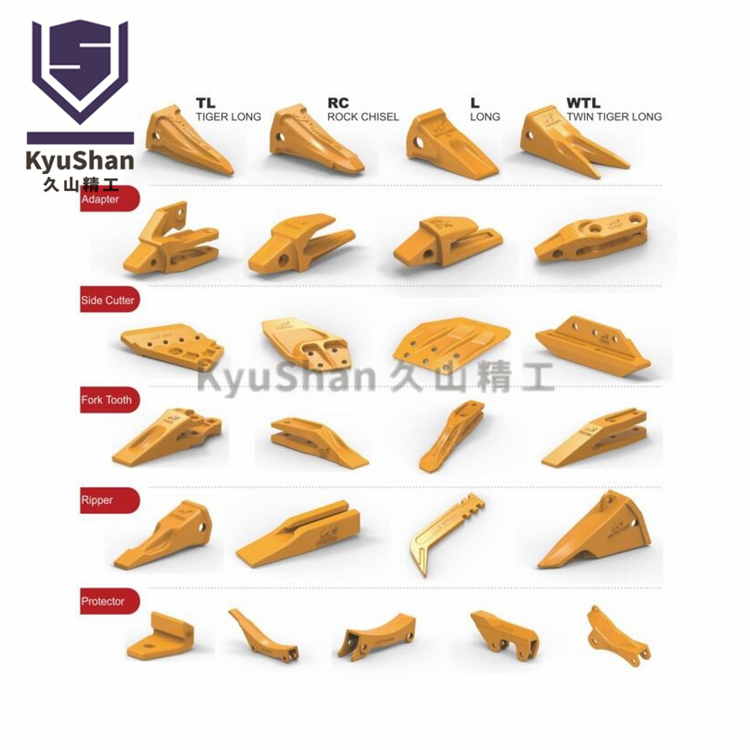

Komatsu Excavator Bucket Teeth

| Name | Komatsu Excavator Bucket Teeth |

| Product Number | All Part Numbers You Need |

| Condition | Original Brand New |

| MOQ | 1 Piece |

| Payment | T/T, Western Union, Paypal, etc |

| Standard or Nonstandard | Standard |

| Delivery Time | In 3 Days |

| Packing | Wooden Box |

| Warranty | 6 Months |

| Transport | By sea/air/express (DHL/FEDEX/TNT/UPS/EMS/City-line) |

The wear of the tooth seat is also very important to the service life of the komatsu bucket teeth of the excavator. It is recommended to replace the tooth seat after the tooth seat is worn out by 10%. There is a large gap between the tooth seat and the komatsu bucket teeth with excessive wear. The matching of the bucket teeth and the tooth seat and the force point have changed, and the bucket tooth is broken due to the change of the force point.

The driving method of the excavator driver is also critical to improving the utilization rate of the bucket teeth. The excavator driver should try not to retract the bucket when lifting the boom, and pay special attention to the coordination of actions. Some excavator drivers often throw the bucket on the rock with too much force during the action of enlarging the arm and sending the forearm, which will smash or crack the komatsu bucket teeth and damage the forearm.

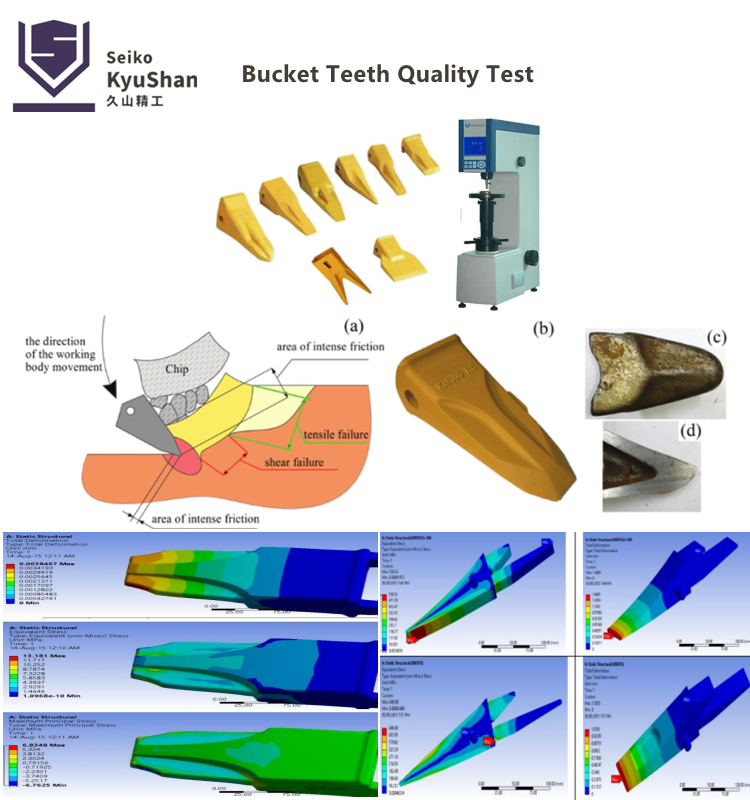

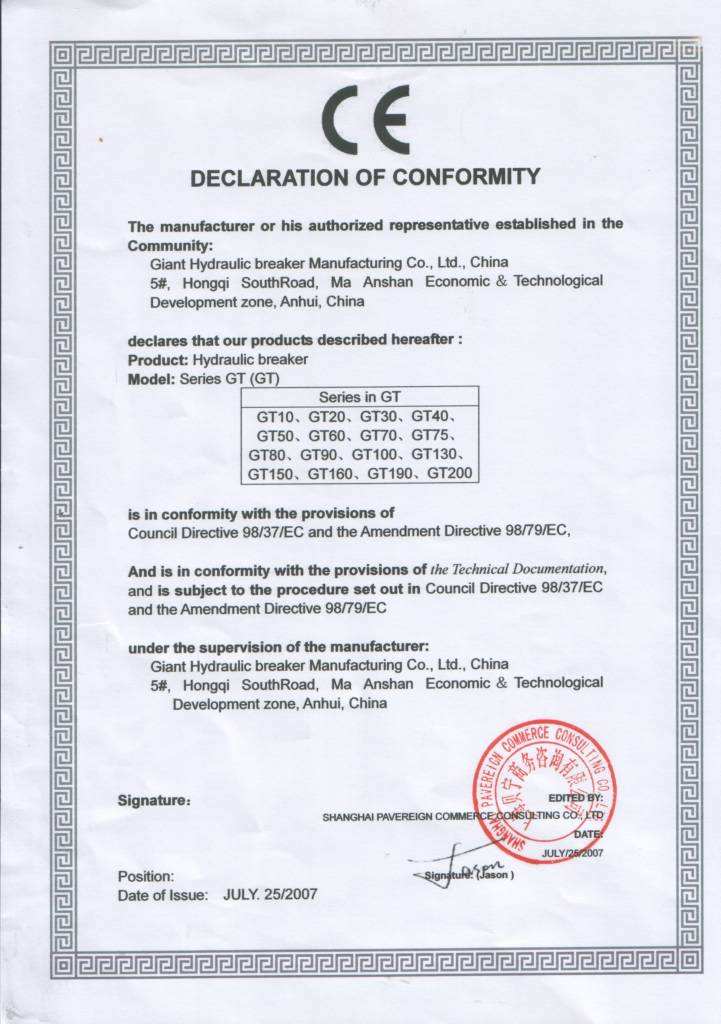

The advanced water glass lost wax casting process produces precision steel castings made of ordinary carbon steel and low alloy steel. It is a large-scale professional production base for investment casting in China. It integrates precision foundries and machining plants with annual production. More than 7,000 tons of precision castings and various types of precision castings are mainly exported to Europe, America, Japan and many other countries.

The enterprise implements the modern enterprise management mode, fully implements the ISO9001:2000 quality management system and injects the "TQM" mode, and through the effective transformation of software and hardware, advocates the ISO14000 environmental protection management system, in order to achieve a win-win situation between enterprise performance and environmental performance.

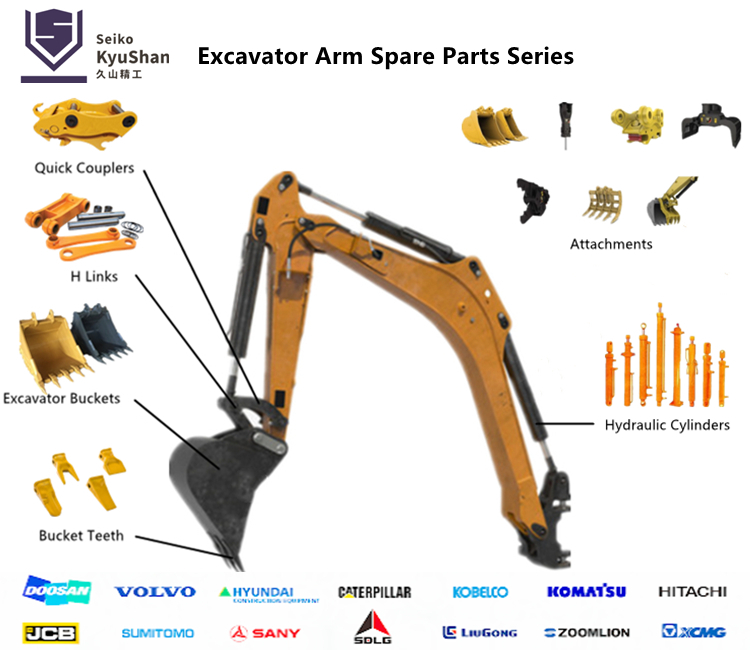

We are a comprehensive supplier of excavator accessories, if you have excavator accessories needs, please contact us, we will be glad to receive your inquiry!

Sales Manager:Liam Cheng Wechat/Whatsapp:+8616653175111