Excavator Bucket

-

Hot

Standard High Quality Cat 320 Bucket

The excavator buckets we built for Cat 320 have passed iso9001 and sgs certification, and have been sold in China for many years, and also sold to many countries. Domestic and foreign customers have high praise for our cat 320 buckets. Our Cat 320 buckets are reliable, durable, and affordable, making them your best choice!

Send Email Details -

Hot

Caterpillar Excavator Cat 308 Bucket

Factory directly sell cat 308 bucket for all tonnage excavator

Send Email Details

Premium quality,Competitive price,Fast shipping, Quality guaranteed.

Feature:

1,Fully armored by HB400/450/500 wear plates(Hardox 400/450/500 on side wear pads bottom wear bars, inside liners)

2,Extra protected by casting shrouds(Side rail shrouds,heel shrouds,lip shrouds) for cat 308 bucket

3,High tensile steel on lip and side rail plates

4,rock duty ground engaging parts+4140 bucket pins

5,Strengthened upper bem structure+ reinforced gussets

6,Larger capacity ( dual radius contour+deep belly) of cat 308 bucket

7,Wide range teeth system available -

Hot

All Kinds Of Side Cutter Excavator Bucket Cutting Edge Replacement

Material of excavator side cutter:Alloy steel/Carbon steel etc, such as T1,T2,T3,T4

Send Email Details

Heating Treatment:Quenching and tempering treatment

Teeth Hardness of excavator side cutter: HRC47-52 ,Impact value >=16J

Adapter Hardness:HRC34-38 ,Impact value >=25J

Colors of excavator side cutter:Yellow/Greem/As customers requested

Work Condition of excavator side cutter:With excellent elongation and tensile strength, suitable for many different hard working conditions.

Under normal circumstances, the excavator side cutter, bottom plates, side plates, and tooth roots of the bucket are the places with relatively large wear and tear, so to regularly observe the wear degree of these places, and if necessary, strengthen these places. . -

Hot

Komatsu Bucket Pins And Bushing For Excavator

• Using steel as raw materials of komatsu pins and bushings, which are provided by domestic famous manufacturer; forging again and again to make forming, to make internal organization more tight, and increase komatsu pins and bushings'wear-resistance. Or depend on your need.

Send Email Details

• Using advanced machine in strict accordance with komatsu pins and bushings’ technical requirement to manufacture and ensure each position’s size which convenient to equip.

• Having international advanced heat treatment technology, using carburization treatment on them, guarantees their surface’ s thickness of carburized layer and hardness; meanwhile good core . -

Hot

All Kinds Of H Link For Excavator Linkage Part

1. Materials of excavator h link: Q235

Send Email Details

2. Features of excavator h link: Large bucket capacity, and large open area,large stowing surface,smooth connection with

excavator and durable working performance.

3. Certifications: ISO9001 &TS and CE certification.

4. Production quality testing: hardness testing,welding quality inspection,dimensional inspection and

visual inspection etc.

5. Competitive products: good quality with reasonable price.

6. Strong wear resistance and long life span, can be used in harsh environment and serious abrasion.

7. Professional: our factory has over 10 years working experience in casting and forging process and

manufacture. -

Hot

All Part Numbers Digger Bucket Pins For Excavator

The digger bucket pins is wear part for excavator bucket attachments.

Send Email Details

There are some different materials for digger bucket pins. 45# carbon steel, 40Cr and 20CrMnTi are mainly three materials for them.

Besides raw materials, heat treatment is also very important for its quality. The digger bucket pins and bushing after thermal refining and surface treatment is assured the enough inside hardness and outside wearlessness. -

Hot

Caterpillar Cat Excavator Bucket Pins And Bushings

1)high strength cat excavator bucket pins and bushings

Send Email Details

2)various cat excavator bucket pins and bushings

3)ISO9001:2000 cat excavator bucket pins and bushings

4)40Cr 45# cat excavator bucket pins and bushings

5)the bucket pin we produce are of superior quality

6)we have registered our own Brand for many years

7)therefore we guarantee the quality about the cat excavator bucket pins and bushings we supply.

8)our bucket pin enjoy a good reputation and an excellent service in the market. -

Hot

Customized 30 ton Excavator Buckets

30 ton excavator Bucket Processing:

Send Email Details

The fabrication adopts state of the art technologies such as CNC flame cutting,CNC laser plasma cutting and CNC turrett punch.

The welding of various components and structure parts employs electrical arcs,trade package and robot welding technology.

The production of hydraulic components is completely CNC contrelled. -

Hot

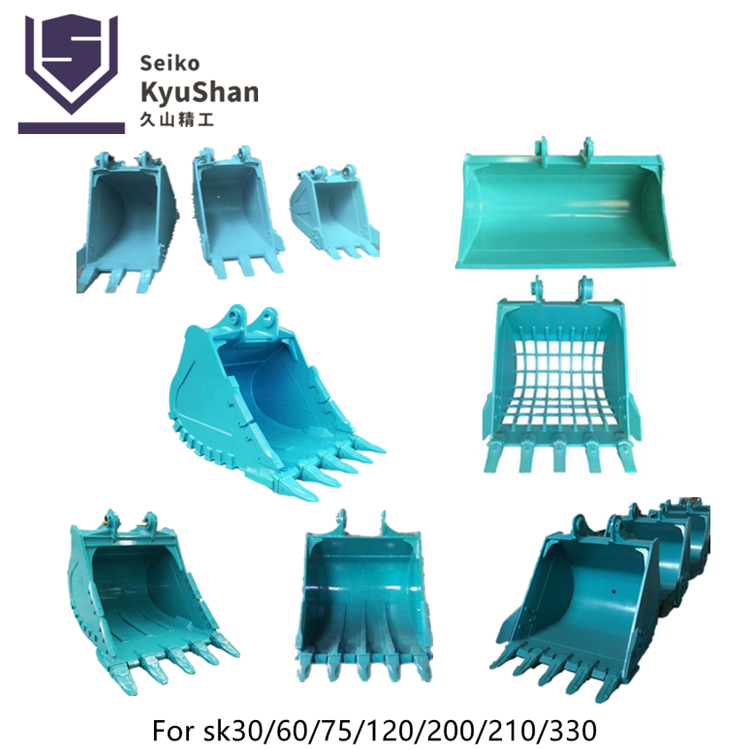

All Kinds Of Kobleco Bucket Excavator

Supiror Performance of Kobelco Bucket

Send Email Details

1. Quenched&Tempered Alloy Steel 140,000-150,000 psi MIN. Yield, 320-400 BHN is used in cutting edge, lower sidecutter sections, wear strips & side wear plates.

2. Optimized profile for better filling & dumping

Enhanced Durability of Kobelco buckets

1. Strategic placement of HARDOX500 wear material in the cutting edge, side cutter and bottom corner to reduce wear.

2. High strenght wear strip configuration, affords the best possible protection to the bottom of the kobelco bucket.

3. All welding is done by skilled worker with, at least, 4 years of excavator attachments' welding experience.

Superior Lead Time

1. Most sizes available in 5-7 working days(excluded shipping)

Reasonable Price of kobelco bucket

1. Manufactured in China with lower labor cost and guaranteed quality.